Considérations essentielles avant d'installer une pince de tuyau

Évaluation de l'état de la ligne d'eau principale

Avant de choisir un pince de tuyauCommencez par vérifier le pipe’ S forme. Les techniciens doivent détecter des signes clairs de rouille, de vieilles corrections, de courbes ou de changements de couleur.

Vous devez déterminer le type de fuite. Est-ce un trou minuscule, une fente mince, ou une rupture complète de l'articulation? Pour les petites fuites, les dommages locaux, la rouille ou les tuyaux facilement accessibles, un remède peut fonctionner bien. Et ces réparations ponctuelles peuvent arrêter les grands dommages causés par l'eau. De plus, ils économisent souvent de l'argent.

Spotter le matériau du tuyau est tout aussi clé. Est-ce PVC, cuivre, fonte ou acier galvanisé? La pince doit correspondre. Les pinces de réparation conviennent généralement à de nombreux types. PVC, cuivre, acier, fonte – la plupart des types ont une bonne correspondance.

Choisir la bonne pince pour la réparation

Après avoir vérifié le pipe’ s état, choisir la meilleure pince devient plus simple. Mais c’ S est toujours très important. La pince doit s'adapter au tuyau’ taille et épaisseur juste juste pour une tenue serrée. Une pince trop petite ou trop grande peut ne pas bien étancher. Ou cela pourrait causer plus de dommages.

La pince’ Le matériel compte beaucoup aussi. Si votre installation est confrontée à de fortes risques de rouille, comme l'eau salée ou les produits chimiques, choisissez-en un parmi des matériaux résistants à la rouille, tels que l'acier inoxydable. Pour la résistance sous pression et la longue durée de vie, les pinces de réparation de tuyaux en acier inoxydable se distinguent comme un choix de haut niveau.

Les pinces sont disponibles dans plusieurs styles pour différents problèmes:

- Pinces à cercle complet pour les dommages ronds

- Pinces de fuite à broche pour petites perforations

- Pinces à cloche pour fentes articulaires

Importance de la compatibilité matérielle

Mettre différents métaux ensemble peut déclencher la corrosion galvanique. Cela’ s une réaction chimique rapide qui dévore à la différence des métaux touchant. Pour sauter cela, Match comme les métaux lorsque vous le pouvez. Ajoutez des couches de barrière si contrairement aux métaux doivent toucher. Choisissez des pinces en acier inoxydable pour une faible réaction et une longue utilisation.

Pinces en acier inoxydable Durez plus longtemps et réagissez moins. Cela aide beaucoup dans les endroits humides ou les endroits avec des produits chimiques durs.

Techniques d'installation pour un étanchéité efficace

Préparation de la surface du tuyau pour l'application de pince

Une bonne installation de pince de tuyau commence par préparer la surface. Essiégez la saleté, la rouille ou la graisse. Pour les vieux tuyaux, utilisez une brosse à fil ou un ponçage léger. Cela permet au joint de s'asseoir à plat et d'étanchéité sur le tuyau.

Faites aussi ceci :

- Liser les points rugueux pour protéger le joint

- Libérez toute la pression de la ligne d'abord

Si vous les manquez, le joint peut échouer. Ou le sceau a gagné’ t maintenir - et le fix s'effondre.

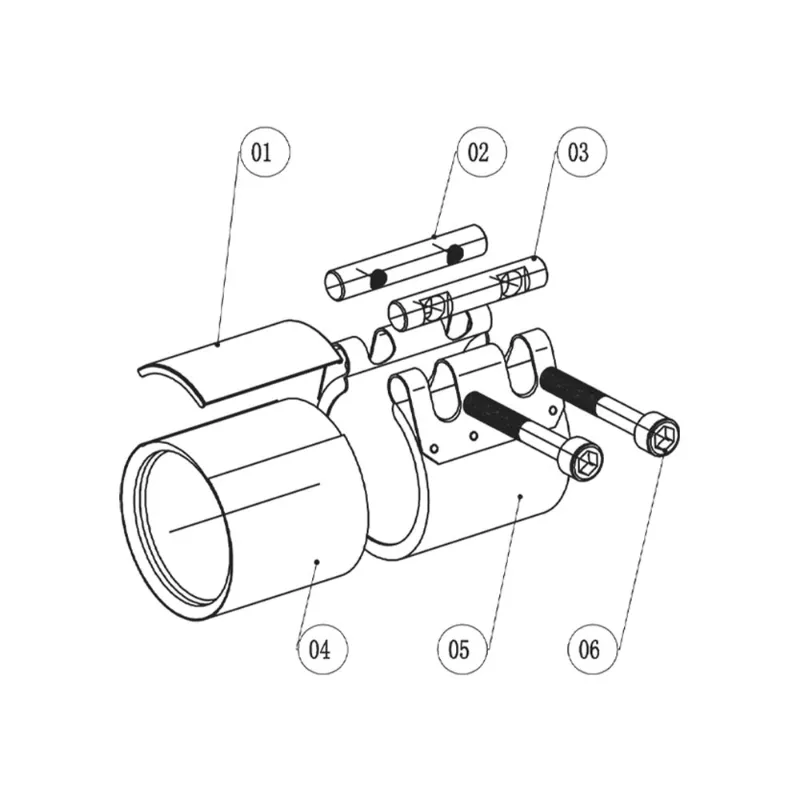

Positionner et aligner correctement la pince

Faire le droit compte le plus. Centrez la pince juste sur la fuite. Aligner même avec le pipe’ longueur s. Le joint doit couvrir le tuyau en douceur, sans plis ni déplacements.

Une petite inclinaison lorsque vous la posez peut répandre la pression de manière inégale. Ensuite, les fuites peuvent continuer ou revenir.

Meilleures pratiques de serrage de boulons

Serrez les boulons dans un ordre croisé. Cela presse le joint de manière uniforme. Prenez votre temps. Trop de force peut endommager le joint. Trop peu laisse l'eau glisser. Si le fabricant donne des numéros de couple, adhérez-vous à eux.

Une mauvaise utilisation du couple est la principale raison de fuites après avoir installé des pinces de tuyaux.

Facteurs de conception qui influent sur les performances à long terme

Le rôle du matériau d'étanchéité dans l'efficacité d'étanchéité

Le type de joint doit s'adapter au tuyau’ contenus et les environs. Pour les lignes d'eau potable, l'EPDM fonctionne bien. Il résiste aux changements d'eau traitée et de chaleur. Les joints NBR conviennent mieux aux taches avec de l'huile ou des produits chimiques.

Assurez-vous que le joint manipule:

- Le type liquide (eau, gaz, chimique)

- Les niveaux de chaleur

- Règles d'eau potable si nécessaire

Considérations de distance et de longueur de pince

Les pinces plus grandes scellent mieux sur de grands dommages. Ils répartissent la poussée de manière uniforme. Si vous avez besoin de plus d'un. Gardez de l'espace entre eux pour éviter l'accumulation de stress. Laissez chaque pince couvrir son propre endroit seul.

Cela empêche les zones de pression de se chevaucher. Et il empêche les joints de se déplacer hors de place.

Facteurs environnementaux qui influent sur la durabilité des pinces

Les choses extérieures comme l'acide du sol, les rayons solaires et les changements de gel-fusion peuvent réduire la durée de vie de la pince. Pour les lignes enterrées, la mauvaise rouille du sol est une grande inquiétude.

L'acier inoxydable lutte mieux contre ces taches difficiles. Alors il’ s un achat intelligent pour des réparations durables.

Entretien et inspection après installation

Surveillance des signes de dégradation du sceau au fil du temps

Même une bonne installation peut s'usurer avec le temps et la météo. Vérifiez maintenant et ensuite :

- L'eau ruisselle près des côtés de la pince

- Indications de rouille par les boulons

- Push-out du joint sous la pince

Ces indices peuvent signifier des boulons lâches ou des joints fatigués.

Quand redresser ou remplacer les pinces dans les lignes de service

De petites gouttes peuvent apparaître peu après l'installation. Cela se produit à partir de la déposition de choses ou des gonflements de chaleur. Serrez lentement les boulons avec le couple droit. Recherchez les fuites qui continuent à venir

Si vous voyez l'usure de l'utilisation ou la rouille claire sur un pince de réparation de tuyaux en acier inoxydableÉchangez-le. Il’ c'est plus sûr que de le réparer encore et encore.

Intégration de composants professionnels dans les systèmes de réparation

Avantages de l'utilisation de produits de réparation conçus par des leaders de l'industrie

Les pinces fabriquées par des professionnels, de fabricants solides, donnent une qualité et un travail constants. Les matériaux correspondent au travail. Les contrôles réduisent les erreurs de configuration. Cela conduit à moins de travail de suivi et de corrections qui restent.

Comment Conflex Solutions soutient des réparations fiables de lignes d'eau

Conflit Solutions fait fortes pinces de réparation de tuyaux en acier inoxydable pour de nombreuses tailles de tuyaux. Leurs configurations ont atteint les règles de niveau utilitaire. Et ils gardent la configuration simple.

Ils facilitent l'installation et fonctionnent bien dans les tâches clés comme la réparation des lignes d'eau principales. Cela aide les techniciens sur le terrain et les gestionnaires d'actifs.

Intégration des composants Conflex dans les protocoles de maintenance standard

L'utilisation de pièces Conflex dans les réparations quotidiennes ajoute des moyens stables. Les mêmes tailles réduisent les tracas de stock. Les guides pour les pinces correspondent au type de dommage. Cela réduit la formation et réduit les erreurs de configuration pour les équipes et les sites.

FAQ

Q: Quelle taille de pince de tuyau dois-je utiliser?

Mesurez soigneusement le diamètre et l'épaisseur de la paroi de votre tuyau - les pinces doivent correspondre exactement pour un étanchéité approprié.

Q: Puis-je installer une pince de tuyau sur une ligne d'eau active?

Non. Toujours dépressurer et drainer la ligne avant d'effectuer toute réparation principale de la ligne d'eau.

Q: Combien de temps durent les pinces de réparation de tuyaux en acier inoxydable?

Avec une installation et une inspection appropriées, ils peuvent durer des décennies, même dans des environnements difficiles.

Q: Est-il acceptable d'utiliser plusieurs pinces près d'elles ?

Oui, mais maintenez l'espacement pour éviter le chevauchement des contraintes et s'assurer que chaque pince scelle correctement sa propre zone.

Q : Pourquoi choisir Conflex plutôt que les marques génériques ?

Les pinces Conflex répondent aux normes de qualité utilitaire avec des dimensions et une qualité de matériau constantes, ce qui minimise les défaillances d'installation.