De nombreux projets d’infrastructure doivent relier des systèmes anciens à des matériaux modernes. Un adaptateur de bride universel restreint offre un moyen fiable de combler ces écarts.

Ce raccord gère efficacement les variations de tailles et de types de tuyaux. Avec un adaptateur de bride universelles équipes peuvent connecter des tuyaux en fonte au PVC et au PE sans perturbations majeures.

Pourquoi tant de projets ont encore besoin de la fonte pour la transition vers le PVC / PE

Les anciens réseaux de tuyauterie dépendent fortement de la fonte. Lors de la mise à niveau ou de l'expansion, de nouveaux tuyaux en PVC ou en PE entrent souvent en jeu. Les projets peuvent’ t permettent des arrêts complets. Les lignes d'approvisionnement en eau ou de production doivent continuer à fonctionner. Ce mélange se produit dans les villes qui mettent à jour les réseaux d'eau ou les lignes d'égout.

Des fabricants comme Conflex rencontrent ce défi chaque jour dans les projets de rénovation, où les entrepreneurs doivent relier de nouveaux réseaux en PVC ou PE à des réseaux en fonte vieillissants sans compromettre la fiabilité.

Pourquoi choisir un adaptateur de bride universel au lieu de simples accouplements en caoutchouc?

Les couplages en caoutchouc fonctionnent bien pour les drains à basse pression. Ils’ re flexible et facile à frapper. Mais dans les lignes pressurisées? Pas toujours le meilleur pari.

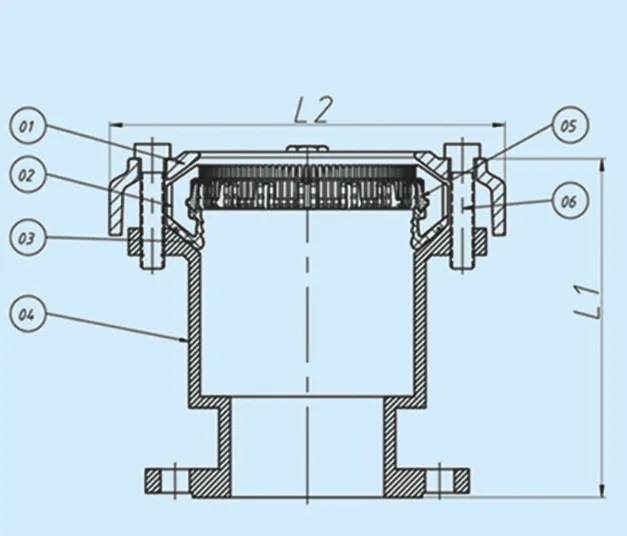

Un adaptateur de bride universel s'adapte à différents diamètres extérieurs. Il fonctionne avec la fonte, le PVC, le PE, même le fer ductile. Les faces des brides s'alignent soigneusement avec des vannes ou des tuyaux courts. La normalisation accélère le travail. Allez pour la version restreinte pour arrêter le tirage des tuyaux. Cela’ clé dans les systèmes dynamiques.

Ce joint de tuyau mécanique brille là où les forces de poussée entrent, comme près des virages ou des tees. Un adaptateur de bride mécanique assure cette adhérence supplémentaire.

Vérifications clés avant de vous connecter: état, diamètre et pression

Évaluer l'état de l'ancien tuyau en fonte

Commencez par l'ancien tuyau en fonte. Recherchez des forages lourds, des formes ovales ou des fissures. Si le mur’ s trop mince, sauter la connexion là. Swap dans une courte section à la place.

Confirmer les dimensions et les normes

Ensuite, les tailles sont importantes pour la connexion de tuyaux en fonte à PVC. Mesurer le diamètre extérieur et le DN nominal. Adaptateurs universels liste une plage, disons DN100: de x à y mm. Cela couvre les variations.

Confirmez la pression nominale

Les valeurs de pression comptent aussi. Connectez un tuyau en fonte au PE? Correspondance avec le système’ s demandes. PN10 convient à des pressions modérées, comme dans la distribution d'eau. Le PN16 supporte des charges plus élevées, courantes dans les lignes industrielles.

Conditions du site

Choisissez mal, et des fuites ou des éclats se produisent. L'installation au sol, la poussée sur les coudes, les espaces serrés - tout cela influe sur le choix de l'adaptateur de bride PN10 PN16 et de l'ancrage.

Les fabricants les plus réputés, y compris Conflitfournir des tableaux de dimension et de pression nominale pour chaque taille d'adaptateur de bride universelle, qui doivent toujours être vérifiés avant de commander ou d'installer.

Étape par étape: connecter l'ancienne fonte au nouveau PVC ou PE avec un adaptateur de bride universel restreint

Les étapes ci-dessous décrivent un flux de travail typique lors de l'utilisation d'un adaptateur de bride universel restreint, tel que la gamme DN100-DN300 offerte par Conflex. Se référer toujours aux instructions d'installation spécifiques fournies avec le produit.

1. Préparez et coupez les tuyaux

Soutenez l'ancienne fonte en toute sécurité d'abord. Marquez la ligne de coupe. Utilisez une scie ou une coupe pour trancher. Débroyer les bords avec un filet ou une broyeuse.

Gardez cette coupe droite. Il aide l'anneau d'étanchéité à s'asseoir même. Les extrémités inégales entraînent des points faibles.

2. Nettoyer et mesurer les extrémités de Spigot

Éliminez la rouille, la saleté, les vieux revêtements. Descendez pour nettoyer le métal ou le plastique.

Mesurer le diamètre extérieur. Assurez-vous qu'il convient au adaptateur de bride universel contraignant‘ gamme s. Connectez le tuyau en fonte au PVC ici? Vérifiez les deux extrémités.

3. Assemblez l'adaptateur de bride sur le nouveau tuyau PVC/PE

Coulisse sur le corps de l'adaptateur, bague d'étanchéité, glande. Alignez les marques d'insertion. Le PVC est rigide. PE plie plus. Serrez uniformement pour éviter les points de contrainte lorsque vous connectez un tuyau en fonte au PE.

4. Positionnez le tuyau en fonte et rassemblez les faces de bride

Placez la pointe en fonte à la bonne distance. Si vous vous connectez à une vanne ou à un tronçon à bride, ajoutez un joint. Boulon en diagonale pour une pression uniforme.

5. Serrez les boulons et activez le système de retenue

Boulons de couple en motif étoile. Pas de précipitation. Le dispositif de retenue utilise des coins ou des dents pour mordre la paroi du tuyau. Cela verrouille contre le retrait. Respectez le couple recommandé. Surserrer déforme les choses.

6. Essai de pression et contrôles finaux

Remplissez lentement, augmentez la pression. Attention aux gouttes aux articulations. Redressez les boulons si nécessaire. Les normes exigent des tests appropriés sur les lignes de pression. Don’ t juste eyeball.

Meilleures pratiques pour éviter les fuites et le retrait des tuyaux

Les joints en caoutchouc seuls peuvent’ t combattre la poussée axiale pour toujours. Au virage, tees, vannes, ajouter la prévention de tirage de tuyaux.

Choisissez un adaptateur de bride universel contraignantOu utilisez des blocs de poussée pour une tenue supplémentaire. Remplissez le sol soigneusement. Compactez-le bien autour des joints. Aucun vide qui laisse les choses changer.

Pensez aussi à la corrosion. Revêtez les extérieurs ou les enveloppez. Cela prolonge la durée de vie des coulisses en fonte et en plastique mixtes. Les meilleures pratiques de joint de tuyaux mécaniques comme celles-ci maintiennent les systèmes serrés.

Erreurs courantes lors de la conversion de la fonte en PVC / PE (et comment les éviter)

Les problèmes de connexion des tuyaux de fonte à PVC apparaissent souvent. Ici’ Quelques-uns à regarder.

- Ignorant les diamètres extérieurs réels et les pressions, juste correspondant aux tailles nominales. Évitez en mesurant l'O.D. et en vérifiant les notations par rapport aux besoins du système, comme dans la section des contrôles clés.

- Connexion droite sur fonte mal corrodée ou déformée. Skip cela ; remplacer d'abord le segment défectueux par une base solide.

- Serrer les boulons en cercle, pas en diagonale. Cela baisse le sceau. Suivez le modèle de couple étape par étape pour équilibrer les forces.

- Oublier la poussée de ligne, conduisant à l'éclatement des joints. Évitez le tirage des tuyaux avec des options restreintes ou des ancres, en particulier à tour.

- Utilisation d'accouplements de drainage sur des tuyaux à pression. Ils manquent de force. Choisissez des types mécaniques adaptés à la charge, comme des adaptateurs de bride universels.

Un montage simple pour un problème de rénovation complexe

La mise à niveau des anciens réseaux en fonte est’ t juste sur l'échange de matériaux. Le vrai truc réside dans les connexions. Un adaptateur de bride universel restreint le rend simple. Il relie facilement différentes tailles et types.

Si vous prévoyez un projet de rénovation, il vaut toujours la peine de partager vos données de tuyauterie et les conditions d'exploitation avec l'équipe technique du fournisseur choisi, comme Conflex, avant de décider d'un détail final de connexion.

FAQ (questions fréquentes)

Q: Quelle est la meilleure façon de connecter un ancien tuyau en fonte à un nouveau tuyau en PVC ou en PE?

La méthode la plus fiable, en particulier pour les applications à pression ou à haute tension, consiste à utiliser un adaptateur de bride universel restreint, qui prend en charge différents matériaux de tuyaux et empêche le tirage.

Q: Un adaptateur de bride universel peut-il s'adapter à la fois aux tuyaux en fonte et en PVC/PE?

- Oui, oui. Un adaptateur de bride universel est conçu avec une large gamme OD pour accueillir les extrémités en fonte, en PVC, en PE et en fer ductile, ce qui le rend idéal pour la modernisation de pipelines en matériaux mixtes.

Q: Ai-je besoin d'un adaptateur de type restreint pour les tuyaux à pression?

Pour les systèmes sous pression ou les emplacements près de courbes, vannes ou tees, un adaptateur de bride universel retenu est recommandé car il verrouille mécaniquement le tuyau pour empêcher le mouvement axial ou le tirage.

Q: Que dois-je vérifier avant d'installer un adaptateur de bride sur un vieux tuyau en fonte?

Vérifiez l'état du tuyau, confirmez le diamètre extérieur réel, vérifiez la pression nominale PN (par exemple, PN10 / PN16) et assurez-vous que l'extrémité du tuyau est propre, ronde et structurellement saine.

Q: Un adaptateur de bride universel peut-il être utilisé pour connecter directement des tuyaux PE?

Oui, mais assurez-vous que l'adaptateur supporte la gamme OD correcte pour les tuyaux PE et suivez les procédures de serrage de boulons appropriées, car le PE est plus flexible que le PVC ou la fonte.