I sistemi fognari comunali gestiscono i rifiuti provenienti da città e città ogni giorno. Smantellamento delle articolazioni svolgere un ruolo chiave in queste impostazioni. Collegano tubazioni e consentono un facile accesso per le riparazioni. Le perdite in queste giunzioni possono causare grandi problemi, come inquinamento o elevati costi di riparazione. La prevenzione delle perdite mantiene i sistemi affidabili e protegge l'ambiente. Le cattive perdite portano a fonti d'acqua contaminate e costose riparazioni.

Cause comuni di perdite nel smontaggio delle giunzioni

Perperdite non’ T semplicemente accadere dal nulla. Spesso provengono da alcuni soliti sospettati nelle condotte delle acque reflue.

Pratiche di installazione sbagliate

Il disallineamento dei tubi è un grosso problema. Tubi che non’ t allinea a destra mettere stress extra sull'articolazione. Ciò porta a lacune dove le acque reflue possono infiltrarsi. Inoltre, la torsione del bullone sbagliata rovina le cose. Se i bulloni sono troppo sciolti o troppo stretti, la tenuta si indebolisce nel tempo. Anche la sequenza di strettamento conta. Saltare l'ordine giusto può causare una pressione ineguale sulla guarnizione.

Avete mai notato come alcuni installatori affrettano il lavoro? Nei progetti comunali impegnati, questa fretta si manifesta in seguito come perdite.

Degradazione e corrosione del materiale

I fluidi reflue sono duri sui materiali. Portano sostanze chimiche che mangiano via guarnizioni e parti congiunte. Nel corso degli anni, questa degradazione crea minuscole crepe. I bulloni e le flange corrodono rapidamente in ambienti umidi e acidi. La ruggine si accumula, e presto l'articolazione può’ T tenere più stretto.

Nei sistemi più vecchi, la corrosione colpisce più forte perché la manutenzione viene trascurata a volte.

Tensioni meccaniche ed espansione termica

Le articolazioni affrontano tutti i tipi di forze. Trazioni assiali, piegatura e tensioni di taglio derivano da spostamenti a terra o traffico pesante sopra. I cambiamenti di temperatura fanno espandere o contrarre i tubi. Questo movimento sforza l'articolazione se’ non è progettato per gestirlo.

I sistemi fognari in climi freddi affrontano questo molto durante lo scongelamento invernale. L'espansione può pop sigilli se ignorato.

Manutenzione e ispezione inadeguate

Nessun controllo di routine significa che i problemi si nascondono. I primi segni di usura, come leggere gocce, vengono persi. Senza monitoraggio, piccoli problemi si trasformano in grandi perdite.

Gli equipaggi comunali sono stretti sottili, quindi le ispezioni a volte cadeno sul bordo della strada. Questo’ s una ricetta per i guai lungo la linea.

Considerazioni di progettazione per ridurre al minimo i rischi di perdite

Un buon design ferma le perdite prima che inizino. Scegli la roba giusta dall'inizio.

Scegliere il materiale giusto per le applicazioni delle acque reflue

Il ferro duttile funziona bene per la forza. Acciaio al carbonio è comune, ma l'acciaio inossidabile combatte la corrosione meglio nelle acque reflue dure. Aggiungere rivestimenti che resistono alla ruggine. Anche le guarnizioni devono resistere alle sostanze chimiche. Le opzioni EPDM o nitrile sigillano resistente ai fluidi aggressivi.

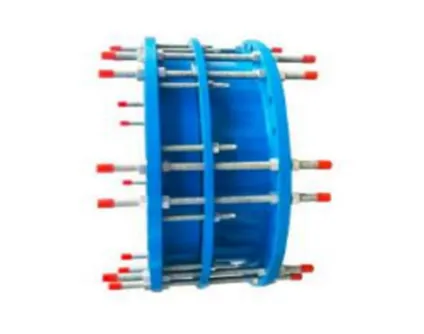

I giunti di smontaggio, come componenti chiave della condotta, consistono in una flangia e un adattatore di flangia. Quando la flangia si muove verso l'adattatore, il giunto si accorcia. Tiralo dall'altra parte e si allunga. Questa configurazione consente di regolare le lacune durante l'installazione di valvole o contatori.

Geometria congiunta corretta e dimensionamento

Flangia dimensioni dovrebbero corrispondere esattamente alle dimensioni del tubo. Lo spaziamento dei bulloni impedisce i punti deboli. Progettazione per alcuni movimenti assiali per gestire disallineamenti o spostamenti.

Questi giunti forniscono flessibilità nelle condotte. Si adattano agli spostamenti dovuti ai cambiamenti di temperatura, alla sedimentazione del suolo o alle vibrazioni. Nei luoghi industriali agiscono come tamponi, assorbendo le vibrazioni di grandi macchine. Ciò riduce l'usura e prolunga la vita del tubo.

Scegliere giunti di smontaggio di qualità

Cercate quelli affidabili come i prodotti Conflex. Sono dotati di caratteristiche per un uso delle acque reflue difficile. La certificazione secondo standard come EN 545 o AWWA C219 garantisce la qualità. Questi giunti impediscono le perdite offrendo tenute strette con guarnizioni di alta qualità resistenti ai prodotti chimici e alla pressione.

Un grande vantaggio dello smontaggio delle giunzioni è la prevenzione delle perdite. Creano una barriera affidabile, mantenendo i fluidi dove appartengono. Se è’ Con acqua, olio o acque reflue, un buon giunto riduce i rischi di fuoriuscita.

Migliori pratiche di installazione

L'installazione imposta il tono per l'intero sistema. Fai bene, e le perdite rimangono lontane.

Allinea i tubi dritto prima di montare il giunto. Ciò evita lo stress subito dal pipistrello. Utilizzare la corretta coppia del bullone - seguire le specifiche del produttore. Serrare in un modello a stelle per una pressione uniforme.

Applicare materiali di sigillatura adeguati. I lubrificanti aiutano i bulloni a scivolare senza irritare. Assicurare spazio sufficiente per la regolazione assiale. Ciò rende spazio per valvole o pompe senza forzare le cose.

Smantellamento delle articolazioni rendere l'installazione facile. Basta sciogliere i bulloni per rimuoverli. Nessuna necessità di taglio o saldatura, che risparmia tempo e salta la necessità di competenze professionali. Per la manutenzione, è’ s una brezza - accesso rapido riduce i tempi di fermo.

Nei sistemi reflue, questa flessibilità brilla. Espandere la rete? Aggiungere sezioni con queste giunzioni senza strappare la vecchia configurazione. Questo’ s modulare e semplice.

Lavorano anche con diversi materiali di tubo. Acciaio, PVC, ghisa: i giunti di smontaggio si adattano a tutti. Questa versatilità si adatta a nuove costruzioni o retrofit.

Strategie di manutenzione per la prevenzione delle perdite

La manutenzione fa funzionare le cose senza problemi. Don’ aspettare le pause.

Ispezione e monitoraggio di routine

Fare controlli visivi spesso. Guarda le guarnizioni per crepe o gonfiore. Bulloni di coppia per spec e notare qualsiasi allentamento. Controllare le condizioni della flangia per la corrosione.

Per i punti critici, utilizzare test non distruttivi come l'ecografia. Identifica difetti nascosti senza smontaggio.

Lo smontaggio delle giunzioni facilita la manutenzione. Lo smontaggio rapido significa meno tempo di fermo per la pulizia o le riparazioni. Nella produzione di sistemi comunali pesanti, ogni minuto conta.

Approcchi di manutenzione predittiva

I sensori tracciano le vibrazioni, la pressione e l'allineamento. Problemi di bandiere dati in anticipo. Sostituire le parti a rischio prima che falliscano.

Questa tecnologia ha cambiato il modo in cui le città gestiscono le acque reflue. Niente più soluzioni reattive: prevedere e prevenire.

Formazione per il personale di manutenzione

Formare gli equipaggi sulle tecniche di gestione. Coprire le cause comuni di perdita in modo da individuarle rapidamente.

Una formazione adeguata paga. Le squadre installano e mantengono meglio, evitando costosi errori.

A volte, la gente dimentica come le giunzioni di smontaggio regolano le lunghezze per gli scambi di valvole. Ricorda loro: semplifica tutto.

Conclusione

Prevenire le perdite nelle condotte fognarie comunali si riduce alle basi. Inizia con un design solido: materiali giusti, dimensioni corrette, giunzioni di qualità come Conflex. Installare con attenzione con allineamento e coppia in mente. Mantenere attraverso ispezioni, sensori e formazione.

Passi proattivi garantiscono affidabilità. Le giunzioni di smontaggio di alta qualità offrono valore a lungo termine, riducendo rischi e costi. Per i sistemi reflue, questo approccio protegge le comunità e l'ambiente.

Domande frequenti

Q1: Che cos'è un giunto di smontaggio?

Un giunto di smontaggio è un componente di condotta fatto di una flangia e un adattatore di flangia. Regola la lunghezza per creare spazi per l'installazione o la rimozione di valvole, pompe o contatori.

Q2: Perché usare giunti di smontaggio nei sistemi fognari?

Rendono facile l'installazione e la manutenzione, forniscono flessibilità per i movimenti, evitano le perdite con tenute strette e lavorano con vari materiali di tubazione.

Q3: Come lo smontaggio delle giunzioni impedisce le perdite?

Utilizzano guarnizioni di qualità che resistono ai prodotti chimici e alla pressione, formando una barriera affidabile. Una corretta installazione e manutenzione mantengono intatte le tenute.

Q4: I giunti di smontaggio sono economicamente efficaci?

- Sì. - Sì. Risparmano manodopera a causa della facile manipolazione, riducono i tempi di fermo e evitano costose riparazioni o sostituzioni di perdite.

Q5: Quali materiali si adattano a smontare i giunti per le acque reflue?

Ferro duttile, acciaio inossidabile con rivestimenti resistenti alla corrosione e guarnizioni resistenti ai prodotti chimici come l'EPDM.