Киргизүү: Универсалдык флангалык адаптерлердин ролу

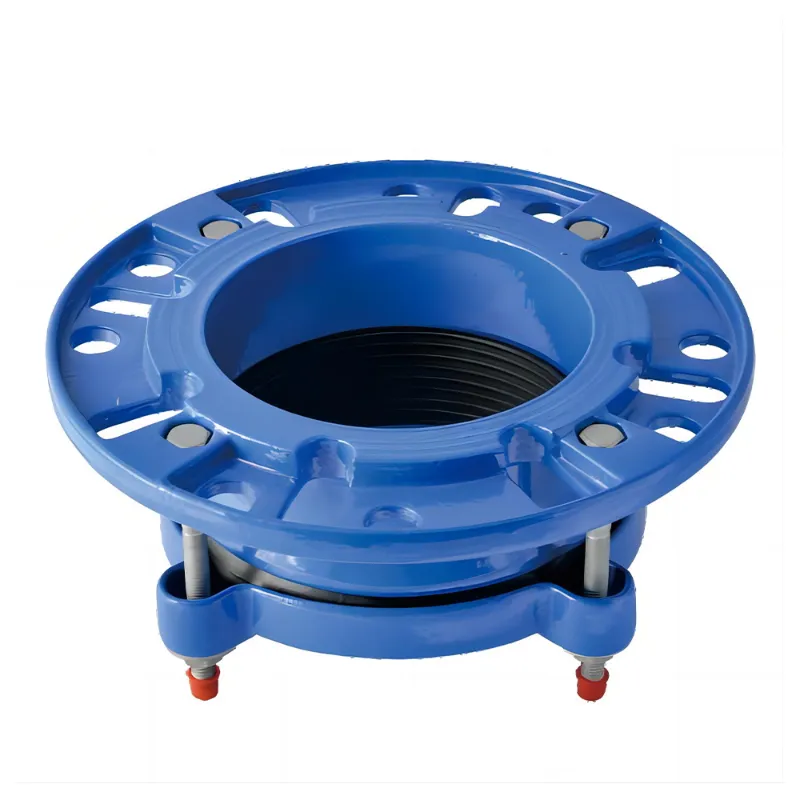

Байланыштар өнөр жай долбоорлорунда маанилүү. Алар бөлүктөрдү бириктирүүдөн башка нерселерди кылышат. Алар системанын жакшы иштешин камсыз кылышат. Универсалдык флангалык адаптерлер жана флангалык адаптерлер ар кандай түтүктөрдү байланыштырат. Бул түтүктөрдүн көлөмү же материалы ар кандай болушу мүмкүн. Адаптерлер ишти тегиз кылат. Алар ошондой эле нерселерди коопсуз сактайт жана агымдарды азайтат.

Бардык туташтыргычтар кыйын шарттарды жакшы башкарбайт. Басым, суу же химиялык заттар аларга зыян келтириши мүмкүн. Күчтүү туташтыргычты тандоо негизги. Conflex, ишенимдүү өндүрүүчү, көптөгөн Flange AdaptorsАлардын FBE капталган параметрлери катуу орнотууларга ылайыктуу. Бул адаптерлер орнотууну жеңилдетет. Ошондой эле алар келечектеги оңдоо муктаждыктарын азайтат. Чоң долбоорлордо бул токтотуулардын азайышын жана туруктуу чыгымдарды билдирет.

Fusion Bond Epoxy Coating деген эмне?

Fusion Bond Epoxy (FBE) - атайын порошок каптоо. Ал жылуулук менен металлга коюлат. Порошок ысык бетинде эрилет. Андан кийин ал катуу калканга айланат. Бул калкан дат, химиялык зыян жана кийүүнү токтот.

FBE каптоолору түтүктөрдө, суу системаларында, машиналарда жана химиялык заводдордо кеңири таралган. Бул жерлерде металлды бекем сактоо өтө маанилүү. Адаттуу боёк же галванизациядан айырмаланып, FBE металлга тыгыз жабышты. Ал зыяндан туруктуу коргоо түзөт. Атта жетүү кыйын жерлерде да, FBE менен капталган туташтыргычтар жылдар бою бекем калат.

FBE каптоонун негизги касиеттери

- Corrosion Resistance: FBE капталган туташтыргычтар дат жана бузулууга каршы күрөшөт. Бул ачык, жер астындагы же деңиз долбоорлору үчүн маанилүү. Убакыттын өтүшү менен бузууну, жарылууну жана кымбат оңдоону токтот.

- Жабыштыруу күчүКаптамы металлды бекем кармап турат. Ал тирилгенде же стресстен тышкары да, кабылып кетпейт же кабылып кетпейт.

- Химиялык каршылыкFBE каптоолору туздарды, кислоталарды, базаларды жана башка химиялык заттарды иштетет. Алар өнөр жай түтүктөрү үчүн сонун.

- Температуранын туруктуулугуFBE ысык же муздак шарттарда иштейт. Ал жарылуусуз же кармашын жоготуп, күчтүү сактайт.

- Экологиялык достукFBE VOC чыгаруусу аз. Ал жашыл стандарттарга жооп берет, ошондой эле катуу коргоону сунуш кылат.

FBE капталган универсалдык туташтыргычтарды колдонуунун артыкчылыктары

FBE капталган Universal Flange адаптерлери көптөгөн артыкчылыктарды сунуш кылат. Алар жөнөкөй коргоодон тышкары. Бул туташтыргычтар эң жогорку аткаруу жана узак өмүр сүрөтү үчүн жасалган.

Жакшыртылган туруктуулук

Өнөр жай туташтыргычтарында туруктуулук маанилүү. FBE капталган адаптерлер стрессти чечүүгө жана капталбаган же боёлгон адаптерлерге караганда жакшыраак кийүүгө мүмкүнчүлүк берет. Алар титирөөдөн же катуу колдонуудан келген зыянга каршы турушат. Көп кыймыл көрсөткөн системаларда бул күч бузулууларды алдын ала алат. Орнотуу учурунда кичинекей согушуулар да аларга зыян келтирбейт. Бул шаардык суу системалары, мунай түтүктөрү же фабрикалык машиналар сыяктуу чоң долбоорлор үчүн маанилүү. Бул долбоорлордун убактысы көп.

Жогорку коррозияга каршылык

Раст системаларга кирип чыга алат. Башта кичинекей дат такталары жаман көрүнбөшү мүмкүн. Бирок убакыттын өтүшү менен алар байланыштарды алсыздайт. FBE каптоолору күчтүү калкан катары иштейт. Алар металлды суудан, туздан жана химиялык заттардан коргойт. Бул сырткы жайларда, химиялык заводдордо же деңиздин жанында маанилүү. Мисалы, жээктеги жерлерде туздуу абадан тез тозуу пайда болот. Conflex компаниясынын FBE менен капталган флангалык адаптерлери бул тобокелдикти азайтат. Алар узак убакытка созулат жана ишенимдүү болушат. Жер астындагы түтүктөр да кислоталык же минералдык оор топуракта пайда алышат. Каптама оңдоо чыгымдарын кыскартат жана системанын өмүрүн узартат.

Убакыттын өтүшү менен чыгымдардын натыйжалуулугу

FBE капталган Flange адаптерлери Башында көбүрөөк баалашы мүмкүн. Бирок алар узак мөөнөттө акчаны үнөмдөшөт. Аларды азыраак алмаштырасыз. Өзгөчө кырдаалдарды оңдоо сейрек кездешет. Техникалык тейлөө зарылдыгы төмөндөт. Бул үнөмдөө кошулат. Өнөр жай долбоорлору үчүн, үзгүлтүксүз туруктуу иштөө чоң жеңиш. Алдын ала чыгымдар узак убакытка созулган жабдуулар менен төлөнөт.

FBE капталган универсалдык туташтыргычтардын колдонмолору

FBE менен капталган Universal Flange Adapters абдан ийкемдүү. Алар көптөгөн тармактарда жана долбоорлордо иштешет. Инженерлер жана долбоорлордун жетекчилери көбүнчө аларды ылайыкташтыруучулугу үчүн тандашат.

Өнөр жай жана коммерциялык долбоорлор

- Түбүктөр: FBE капталган адаптерлер ар кандай өлчөмдөгү же материалдардагы түтүктөрдү кошот. Алар буюмдарды бекем сактайт. Бул мунай, газ, суу же химиялык түтүктөрдө маанилүү. Агызуулар же токтотуу убактысы кымбат болушу мүмкүн.

- Механикалык системаларОор машиналарга жана жабдууларга туруктуу туташтыргычтар керек. FBE каптоолору силирүү же таасирлерден кийүүгө каршы турат. Бул системаларды туруктуу кылат.

- Электр системаларыМеталл түтүктөрү же жабдуулар нымдуулукка, чаңга же катуу шарттарга дуушар болот. FBE капталган адаптерлер аларды коргойт. Алар электр көйгөйлөрүнө же коопсуздук тобокелдиктерине алып келиши мүмкүн болгон зыянды алдын алуу үчүн.

Катуу айлана-чөйрөнүн шарттары

FBE менен капталган адаптерлер кыйын шарттарда жарыктайт. Жогорку нымдуулук, туздуу суу же агрессивдүү химиялык заттар аларды тынчсызбайт. Жээктеги жерлерде тоздуу аба тоздоону тездетет. FBE менен капталган флангалык адаптерлер ондогон жылдар бою коопсуз калат. Жер астындагы түтүктөр кислоталык же минералдык бай топурактарда да узак убакытка созулат. Эпоксиддик катмар кийүүнү азайтат. Бул азыраак текшерүүлөрдү жана алмаштырууларды билдирет, бул системаларды ишенимдүү кылат.

FBE менен капталган универсалдык туташтыргычты кантип тандоо керек

Мыкты FBE менен капталган универсалдык флангалык адаптерди тандоо ойлоо керек. Бул факторлорду карап чыгыңыз:

- Долбоордун түрү жана жүктөмүСистеманын басымын, суюктуктун түрүн жана температуранын өзгөрүшүн текшериңиз. Бул туташтыргычтын титирөөлөрдү башкарууга болорун текшериңиз.

- Экологиялык шарттарНимдүүлүктү, химиялык заттарды жана температуранын экстремалдыгын караңыз. Туура каптоо түрүн жана калыңдыгын тандаңыз.

- Стандарттар жана сертификаттар: Адаптердин ISO, API же башка өнөр жай эрежелерине жооп беришин камсыз кылуу. Бул коопсуздукту жана ишенимдүүлүктү камсыз кылат.

- Каптамдын калыңдыгы жана сапаты: FBE катмарынын калыңдыгы жана кармагы аткарууга таасир этет. Орнотуудан мурун кемчиликтерди текшерүү.

Колдуу кеңеш: Каптамды орнотуудан мурун көз менен текшериңиз. Эпоксиддеги кичинекей кемчиликтер кийинчерээк көйгөйлөргө алып келиши мүмкүн.

Конфлекс: Сапаттуу флангалык адаптерлердин булагы

Conflex Flange адаптерлеринин кеңири спектрин жасайт. Алардын универсалдык флангалык адаптерлери көптөгөн өнөр жай жана коммерциялык муктаждыктарга ылайыктуу. Заманбап фабрикалар, сапаттын катуу текшерүүсү жана дүйнөлүк стандарттар оор шарттарда да жогорку аткарууну камсыз кылат. Кошумча күч үчүн FBE менен капталган кийимдер керекпи? Же жөнөкөй орнотуулар үчүн стандарттык? Конфлекстин бардык адамдар үчүн мүмкүнчүлүктөрү бар. Алардын туташтыргычтары бекем, дат менен каршы турат жана жылдар бою тейлөөгө аз муктаж.

Conclusion

Conflexтин FBE капталган универсалдык флангалык адаптерлери туташтыргычтардан көбүрөөк. Алар системанын күчү жана долбоордун ийгилиги үчүн акылдуу тандоо. Алардын тутуга туруштугу, катуулугу жана чыгымдарды үнөмдөөсү аларды түтүктөргө, машиналарга, электр жабдууларына жана башка нерселерге ылайыктуу кылат. Ишенимдүүлүк, узак өмүр жана аз тейлөө талап кылган долбоорлор үчүн Conflexтин FBE капталган адаптерлери камсыз кылат. Алар сизге ишенген натыйжаларды берет.

Көп суралган суроолор

Q1: FBE капталган туташтыргычтары ачык долбоорлор үчүн жакшыбы?

Ооба. Алар сууга, УФ нурларына жана туздарга каршы турушат. Бул аларды сырткы түтүктөр жана жабдуулар үчүн мыкты кылат.

Q2: FBE каптоосу канча убакытка созулат?

FBE каптоолору көбүнчө ондогон жылдар созулат. Алардын өмүрү айлана-чөйрөгө жана кам көрүү ыкмаларына көз каранды.

3-суроо: Бул туташтыргычтар химиялык заводдордо иштей алабы?

Ооба. FBE менен капталган адаптерлер көпчүлүк өнөр жай химиялык заттарын иштетет. Абдан катуу заттар үчүн, спецификацияларды текшериңиз.

Q4: FBE капталган Flange адаптерлери тейлөө керекпи?

Көп эмес. Адатта, дайыма текшерүү жана жеңил тазалоо жетиштүү.

Q5: FBE каптоо сапатын кантип текшерүүгө болот?

Калыңдыгына, жабышышына жана бетинин тегиздигине караңыз. Сапатты тастыктоо үчүн ASTM же ISO сыноолорун колдонуңуз.