Flange adapters and stub end flanges may appear similar at a glance, but their differences in structure, assembly, and function can lead to dramatically different performance in industrial piping systems. For engineers and maintenance planners, understanding these differences is key—flange adapters provide simplified installation, while stub ends offer superior disassembly and inspection capabilities.

Visual Characteristics and Component Structure

Differences in Physical Design

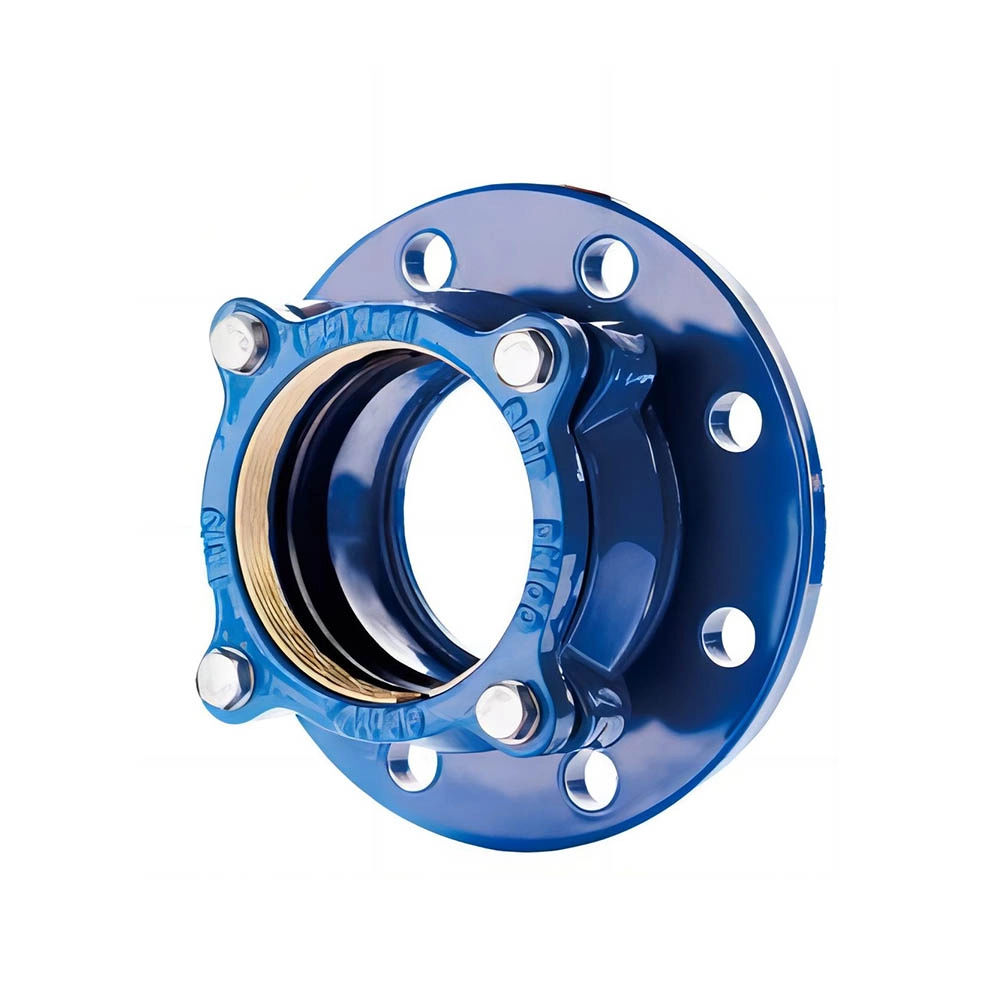

Adaptadores de flange are typically solid, one-piece components that mimic the face of a flange and are often used for direct connection to other flanged equipment. In contrast, stub ends consist of a short length of pipe with a flared end that requires a separate backing flange to complete the connection.

The geometry of the mating surface also differs. A flange adapter has an integral face that aligns directly with the mating flange, providing immediate sealing contact. Stub ends, however, rely on the backing flange to apply pressure across the gasketed joint via the flared pipe end.

Assembly Method and Compatibility

One key functional distinction is that flange adapters can directly connect to a mating pipe flange without any additional parts. This simplifies installation, particularly in systems using plastic or ductile iron pipe. The product is used to connect PE pipe with metal pipe or valve, flowmeter, pressure gauge and other auxiliary equipment.

Stub ends require more steps. They must be welded to the host pipe—usually via butt welding—and then combined with a loose backing flange that facilitates bolting. This assembly method allows for flexibility in alignment but involves more components and time.

Material compatibility also varies. Flange adapters are commonly used in thermoplastic systems like PVC or HDPE, while stub ends are standard in metallic or lined systems such as stainless steel or PTFE-lined carbon steel.

Functional Roles and Performance Characteristics

Typical Applications in Piping Systems

Adaptadores de flange shine in utility and municipal applications, particularly where quick installation or cost-effectiveness is a priority. For instance, water treatment plants often prefer ductile iron flange adapters due to their corrosion resistance and affordability.

Stub ends are favored in chemical processing facilities where pipes undergo frequent inspection or replacement. Their ability to be unbolted without cutting the pipe makes them ideal for stainless steel systems dealing with aggressive media.

Mechanical Strength and Pressure Suitability

Thermoplastic flange adapters may be limited in high-pressure environments. The sealing method adopts socket type, and the dovetail groove design of sealing rubber ring has very good sealing performance, which can meet the sealing pressure of 2.5MPa at most. This means plastic flange adapters are reliable up to moderate pressures but may not suit high-demand industrial use.

Stub end assemblies, when properly welded and paired with robust backing flanges, can handle significantly higher pressures—making them suitable for ASME-class rated piping.

The type of sealing—be it gasket-based or O-ring—also influences pressure retention and leak prevention. Proper alignment becomes essential in both cases to avoid uneven stress distribution.

Installation Considerations and Technical Requirements

Welding, Bolting, and Alignment Needs

Stub ends almost always require butt welding to the main pipeline. This ensures structural strength but increases installation time and demands skilled labor. It’s non-negotiable for high-pressure or hazardous fluid systems.

In contrast, flange adapters often use mechanical restraint or solvent welding depending on the material. This makes them easier and quicker to install, particularly in plastic pipeline systems where thermal fusion is common.

Regardless of type, alignment during assembly is critical. Misalignment can cause gasket failure, excessive stress at the joint, or even system failure under pressure cycling.

Maintenance and Replacement Factors

One practical benefit of using flange adapters is that they may allow quicker replacement of valves or meters without disrupting adjacent piping.

Stub ends excel in corrosive environments where periodic disassembly is expected. Since they separate easily from the backing flange, they’re convenient for lined systems or areas requiring frequent visual inspection.

Long-term maintenance planning should consider access conditions. For buried or embedded piping, fewer joints (as with flange adapters) may be advantageous. For exposed pipelines, especially in harsh chemical environments, stub ends offer better longevity through easy part replacement.

Material Suitability and Resistance Properties

Common Materials Used for Each Type

Adaptadores de flange are widely available in ductile iron, HDPE, PVC, and CPVC. These materials are selected based on corrosion resistance and ease of installation.

Stub ends are usually fabricated from stainless steel (304/316), carbon steel, or specialty alloys like Hastelloy. These metals withstand high temperatures and aggressive chemicals.

Material choice should always reflect the operating environment—temperature ranges, pressure levels, fluid aggressiveness—and not just price or availability.

Corrosion Resistance and Longevity Comparison

Metal stub ends offer excellent corrosion resistance when paired with compatible gaskets like PTFE or graphite. Their mechanical durability allows them to outlast plastic components under harsh conditions.

Plastic flange adapters resist internal corrosion but may degrade when exposed to UV rays or elevated heat. While great for potable water lines or low-pressure gas systems, they might not be suited for industrial chemicals or steam service.

Service life depends heavily on environmental factors—such as exposure to sunlight, saltwater spray, vibration—and load conditions like water hammer.

Sector-Specific Usage Scenarios

Industrial Applications Across Different Sectors

In chemical plants handling acids or alkalis, stub ends combined with PTFE-lined pipes are standard due to their disassembly convenience and chemical inertness.

Municipal water systems often opt for ductile iron flange adapters for their ease of installation and lower cost per joint—especially important when dealing with hundreds of meters of underground pipe.

HVAC systems may use either solution depending on fluid type (chilled water vs. glycol), temperature fluctuation, and access constraints within mechanical rooms.

Influence of Industry Standards on Selection Process

ANSI/ASME B16.9 and B16.5 define dimensional standards for stub ends and their corresponding flanges in high-pressure metal piping systems.

On the other hand, the product is used to connect PE pipe with metal pipe in compliance with AWWA standards—commonly applied in municipal pipeline networks where ductile iron flange adapters dominate.

Working with components that meet these standards ensures predictable performance and simplifies replacement sourcing.

Practical Considerations for Choosing Between the Two

Factors That Influence Component Selection

When selecting between a flange adapter and a stub end:

- Assess system pressure: high-pressure systems favor stub ends.

- Match materials: ensure chemical compatibility with the transported media.

- Weigh cost vs maintenance: flange adapters reduce initial cost; stub ends simplify future inspections.

Another factor is crew expertise—if your team isn’t experienced in welding or dealing with stainless steel assemblies, flange adapters might be safer to install without errors.

Benefits of Proper Component Matching

Matching the right component enhances system reliability by minimizing joint stress and leak risks.

It also helps extend the service life of the system by maintaining consistent seal performance over time—even under pressure spikes or thermal cycles.

Proper selection reduces downtime during maintenance since well-matched parts come apart easily when needed—and go back together just as fast.

Frequently Asked Technical Questions

Q: What is a stub end flange used for?

A stub end flange is used primarily in piping systems requiring frequent disassembly or inspection without cutting or rewelding pipes.

Q: Can flange adapters handle high pressure?

That depends on material type; metal versions can withstand higher pressures than plastic ones, which are generally limited to 2.5MPa at most. The sealing method adopts socket type…which can meet the sealing pressure of 2.5MPa at most.

Q: Does installation of a stub end always require welding?

Yes—most commonly via butt welding—to ensure mechanical integrity under load.

Working with Reliable Manufacturers

Importance of Quality Assurance in Component Supply

Using parts from a trusted manufacturer ensures compliance with dimensional standards like ASME or AWWA. It also guarantees consistent sealing performance across production batches through tight tolerances and tested materials.

Traceability documentation provided by manufacturers allows you to verify material certifications—essential for critical infrastructure projects or regulated industries.

Conflex is a manufacturer specializing in industrial pipe connectors—including ductile iron flange adapters, repair clamps, and flexible couplings—designed for water, oil, gas, and other common pipeline systems.

Evaluating Supplier Capabilities

Make sure your supplier offers both metal and plastic options to match various project requirements. Look into certifications like ISO 9001 or third-party audits that reflect production quality controls.

Equally important is technical support—especially during design phases when selecting between stub ends or a specific pipe flange style can impact overall system layout. Conflex provides engineering support that helps specifiers make optimal choices based on material compatibility, pressure class, and installation conditions.