Pipe systems in factories face temperature changes all the time. These shifts might look small, but they build up over time. They can lead to big shifts and pressure in the pipes. What happens then? Flanges start leaking, gaskets break down, and even the structure gets hurt. One top way to handle this heat growth and stop harm is by picking good 伸缩缝 and bendy pipe parts.

Pipe Thermal Expansion in Industrial Applications

Causes of Thermal Expansion in Piping Systems

Thermal expansion happens when pipe stuff grows from heat. In factory spots, this often comes from:

- Work-linked heat changes (like steam pipes going from room temp to 300°C)

- Outside shifts (day to night or season changes)

- Stuff-specific heat rates — for example, stainless steel grows at a different speed than carbon steel

- Long straight pipe sections, which have more space to stretch out and make stronger push forces

Even a simple 20-meter bit of carbon steel pipe can stretch by almost 24 mm when temps go up by 100°C. That’s plenty to mess up gear setup or overload joints if you don’t plan for it.

Effects of Thermal Expansion on Piping Components

As pipes get longer:

- Straight-line shifts can shove or tug pipe ends, mainly near stuck points

- Big heat pressure builds at turns or bends

- Flanged links, made for tight seals, might bend or slip out of line — hurting gasket seal spots

Expansion isn’t always slow, you know. Quick starts or stops can make sudden jumps that jolt the joints.

Flange Failures Resulting from Thermal Movement

Common Failure Modes in Flanged Connections

Flanges are some of the weakest spots in a pipe setup when heat shifts aren’t handled right. Usual troubles include:

- Gasket pops out, specially when uneven squeeze comes from heat twisting

- Bolts get loose or break from repeated back-and-forth loads

- Leaks from flange surface warp — made worse by bad alignment and bend pressure

These issues can cause surprise stops, safety risks, and costly fixes.

How Thermal Forces Contribute to Flange Damage

Heat growth brings in straight and bend loads. If the setup is stiff and lacks bendiness:

- Growth push goes right to the pipe flange

- Any hold-back — like a pump outlet or building anchor — acts as a pivot, changing straight shifts into bends

- Over time, these pushes tire out the flange surface, bolts, and gasket areas, making the seal weaker

In setups with lots of temp changes, the built-up pressure speeds up breakdowns.

Function of Expansion Joints in Pipe Systems

How Expansion Joints Absorb Movement and Stress

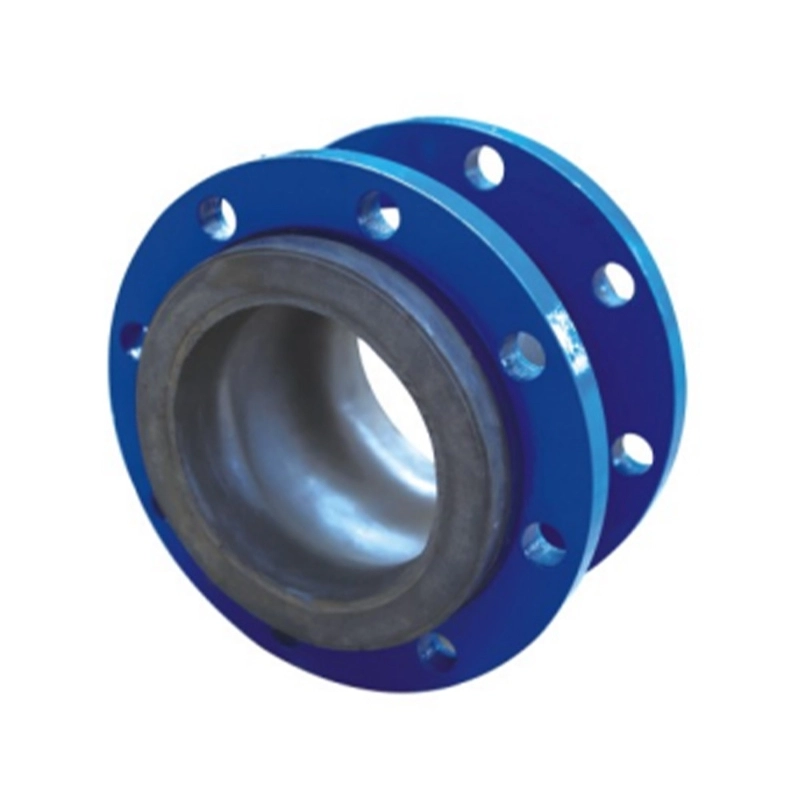

Rubber expansion joints — especially the bendy kinds like bellows — are built to soak up shifts instead of sending them to stiff parts:

- They take in straight motion, side slides, and angle turns

- Cut down force passing through flanges and close fittings

- Can also soften pressure jumps and shakes from spinning machines

A smartly placed flexible pipe joint works like a cushion between the pipe network and touchy bits.

Types of Expansion Joints Used for Flange Protection

The right joint kind depends on the setup’s heat, pressure, and bend needs:

- Metallic bellows: Great for hot steam or gas pipes; they give exact straight fix

- Rubber or fabric joints: Better for low-pressure water or air lines where bendiness counts most

- Gimbal and hinge designs: Used where shifts need guiding on set paths

For instance, Conflex has a bunch of metallic and non-metallic expansion joints fit for hot oil pipes, squeezed air systems, or cool loops. Their items include flexible connectors that guard key flange spots without blocking flow.

Design Parameters for Effective Expansion Joint Integration

Key Factors in Selecting the Right Joint Type

Before picking an expansion joint, builders must think about:

| Parameter | Relevance |

| Operating Temperature | Determines material selection |

| 内部压力 | Affects bellows thickness and ply |

| Media Compatibility | Essential for joint longevity |

| Expected Displacement | Axial/lateral/angular values matter |

| Pipe Size & Layout | Dictates overall joint dimensions |

Missing these details can cause early breakdown or poor pressure relief.

Placement Strategies to Minimize Flange Stress Risks

Spot is just as vital as the specs. Good ways include:

- Putting joints near fixed anchors so shifts stay in check

- Skipping big offsets that could twist the joint part

- Making sure it lines up with planned heat growth path to avoid side push

A bad spot for a joint can cause more trouble than help. It’s often smart to talk with makers like conflex in the planning stage — they can suggest good spots based on heat checks.

Installation Techniques That Protect Flanged Assemblies

Pre-installation Checks and Alignment Procedures

Before setting up any expansion joint:

- Look at pipe lineup fully; off flanges will add early pressure

- Make sure support gaps are right so the joint doesn’t droop from its weight

- Tighten flange bolts even with checked tools — uneven start can lead to leaks under push

These easy steps boost long-run trust a lot.

Maintenance Practices to Sustain Joint Performance Over Time

Even top expansion joints need regular looks:

- Check for metal wear or rubber splits during checks

- Watch high-change lines for added wear

- Track heat change counts if running close to build limits

Active care dodges pricey shocks — specially in setups that go hot to cold daily.

Broader Advantages of Using Expansion Joints in Piping Design

Enhancing System Longevity and Reliability

Adding expansion joints stretches pipe life by:

- Cutting strain at welds and flange surfaces

- Blocking shakes from pumps, air pushers, or spin wheels

- Soaking up rare hard hits from valve shuts or starts

This also cuts the need for often fixing alignment or tightening bolts at flanges.

Improving Operational Safety and Efficiency

By curbing overload at flanged links, expansion joints:

- Lower leak chances that might cause safety problems

- Help keep steady pressure hold without endless tweaks

- Make sure it fits rules like ASME B31.3 which call for pressure checks on heat effects

And maybe most key — they back steady running. Stops from flange bursts cost a lot and you can often stop them.

For folks building or keeping factory pipes, teaming with experts like Conflex gives strong, checked fixes that match safety aims and work needs.

常见问题解答

Q1: Can I use the same expansion joint for steam and water lines?

No — steam requires metallic bellows rated for high temperatures, while water lines can use rubber or fabric joints depending on pressure.

Q2: How often should I inspect expansion joints?

Typically once per year for standard systems; more frequently if operating near design limits or under high thermal cycling.

Q3: Are flexible pipes and expansion joints interchangeable terms?

Not exactly — flexible pipe usually refers to hose-like components; expansion joints are specific devices designed to absorb displacement.

Q4: What happens if I skip using expansion joints in a hot line?

You risk flange misalignment, gasket failure, excessive stress at bends, and even ruptures during thermal expansion.

Q5: Does Conflex offer custom-sized joints?

Yes — Conflex provides tailored solutions based on system specs including diameter, pressure rating, media type, and displacement needs.