管道中的轴向运动往往被忽视,直到出现问题——泄漏、法兰断裂或阀门错位。那么,你实际需要多少轴向行程?答案取决于温度变化、安装条件和未来维护通道等因素。在大多数情况下,做错这一点会导致代价高昂的过度设计或灾难性的失败。让我们明确而实际地分解它。

为什么轴向行程在管道系统中很重要

轴向运动是指管段沿其长度的线性膨胀或收缩。随着时间的推移,它在确保机械完整性和密封性能方面变得至关重要。

管道轴向移动的常见原因

- 热胀冷缩:当管道加热或冷却时,它们会自然膨胀或收缩。这在携带热流体或暴露于室外温度波动的系统中尤其重要。

- 安装错位:在现场组装过程中,实际管道长度可能与图纸存在偏差。公差和装配误差会引入意外的间隙或重叠。

- 地面沉降或结构位移:随着时间的推移,土壤运动或建筑物振动会导致管道从其原始位置移动。

轴向行程余量不正确的风险

- 行程范围过小:如果轴向运动受到限制,热应力会传递到法兰和垫片上。这可能会导致螺栓疲劳或过早密封失效。

- 超大行程范围:另一方面,设计过多的运动会增加成本,并可能降低机械稳定性。

- 密封失效:垫片取决于适当的压缩。轴向约束会扭曲法兰面并影响密封。

管道设计中轴向运动的来源

热胀冷缩

这取决于以下公式:

ΔL=α×L×ΔT

哪里:

- ΔL:轴向膨胀

- α: 热膨胀系数(特定材料)

- L: 原始管道长度

- ΔT:温度变化

例如,一根ΔT为40°C的20米钢管可以膨胀约9.6毫米。将其乘以多个段,数字很快就会加起来。

安装公差和施工偏差

在现实世界中,即使是精心策划的安装也很少能完美对齐。多个接头之间的微小错位会导致累积的轴向位移。纠正这些问题需要连接点的灵活性。

阀门拆卸或更换的维护要求

可拆卸连接器 是管道系统的重要组成部分。当需要维护或更换管道中的关键部件(如阀门、水表、流量计等)时,这些部件的法兰和管道之间需要留有间隙。没有足够的轴向空间,技术人员无法拆卸部件进行维修。A. 拆卸关节 允许人们将管道移动到刚好能安全拉出阀门的位置。

估算所需轴向行程范围

轴向行程计算的实用方法

简化计算通常就足够了:

轴向行程=α×有效长度×最大ΔT安装裕度

包括:

- 材料的α(例如,钢≈12×10⁻⁶/°C)

- 锚之间的管道长度

- 预期最大温差

- 装配偏差的小缓冲区

常见应用的推荐范围

| 应用类型 | 典型轴向行程范围 |

| 公用水 | 每个接头10-30mm |

| 市政管道 | 20-50毫米 |

| 工业管道 | 高达100毫米或以上 |

更高的压力和温度需要更大的范围和更强的补偿组件。

安全裕度在设计中的重要性

虽然计算提供了一个很好的估计,但始终要为意外的变化增加应急资金,尤其是在旧的基础设施或容易发生地震活动的地区。

拆卸接头在管理轴向运动中的作用

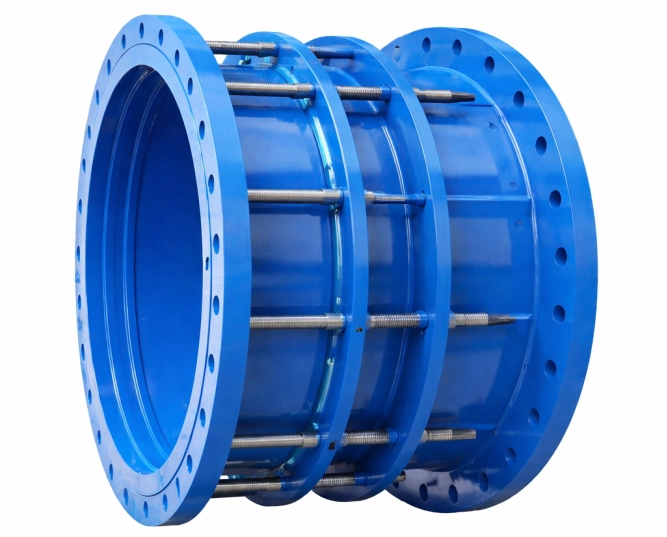

拆卸接头如何提供可调节的行程能力

当法兰朝向法兰适配器移动时,法兰的长度进入法兰适配器的内部,连接器的总长度变短。当法兰从法兰适配器移开时,法兰的长度会伸出法兰适配器,连接器的总长度也会变长。这种伸缩机制允许安装人员预先调整接头,以适应实际的现场条件。

使用可拆卸连接器的目的是方便管道阀门和部件的安装和拆卸。这些连接器允许纵向调节,使阀门能够插入管道中的所需位置。

conflex是一家专业生产工业管道连接产品的制造商,提供一系列为水、石油和天然气系统量身定制的拆卸接头。他们的解决方案简化了安装和维护,同时适应了热运动。

与刚性法兰连接相比的优势

- 无需切割管道即可轻松更换阀门

- 吸收热膨胀引起的微小位移,而不会增加应力

- 即使竣工条件与设计不同,也有助于在安装过程中对齐组件

泄漏是任何管道系统的噩梦。它们会导致体液流失,破坏周围环境,甚至构成安全隐患。即使系统轻微移动,拆卸接头也能保持密封的完整性,从而缓解这种情况。

将轴向行程需求与产品选择相匹配

按公称直径(DN)和压力等级(PN)划分的典型轴向范围

| 公称直径(DN) | 常见轴向范围(mm) | 压力等级(PN) |

| DN100至DN300 | 30–50 | PN10–PN16 |

| DN400至DN1200 | 50–100 | PN10–PN25 |

由于膨胀力较大和节段长度较长,较大的直径往往需要更多的轴向间隙。

VSSJA B2F型关节的应用适用性

这种类型提供拆卸能力和轴向补偿。适用于:

- 水处理系统

- 暖通空调管道网络

- 消防系统

- 工业设施中的工艺管道

对于无法选择停机的高需求应用程序,Conflex VSSJA B2F 该系列具有内置的耐用性和可调节性。

选择前审查技术规范的重要性

目视检查不会告诉你接头是否符合你的设计公差或压力要求。始终验证制造商数据表中的规格,而不是依赖过去的项目经验。

常见问题解答

Q1:如果我的管道中没有足够的轴向行程,会发生什么?

应力将在连接点处积聚,可能导致垫片故障或法兰变形。

Q2:拆卸接头也可以处理横向或角向运动吗?

它们主要处理轴向运动。对于横向或角位移,柔性联轴器可能更合适。

Q3:是否有必要在每个阀门上安装拆卸接头?

并非总是如此,但强烈建议在泵、流量计或大型隔离阀等关键点使用它们。

Q4:如何计算塑料管的热膨胀?

使用相同的公式ΔL=α×L×ΔT,但系数更高。例如,HDPE的α约为150×10⁻⁶/°C.

Q5:Conflex是否为特殊项目提供定制的轴向范围?

是的,Conflex可以根据您的材料、压力等级和长度要求定制拆卸接头。