Las tuberías de HDPE se agrietan, se fugan o pierden juntas después de años de servicio. Una explosión en una tubería de agua puede inundar las calles en minutos. Un goteo lento en una línea de alcantarillado se convierte en un caos costoso. Las reparaciones requieren enlaces rápidos a válvulas metálicas, bombas o secciones de acero antiguas todavía en el suelo.

Las correcciones estándar quedan cortas aquí. La soldadura de HDPE al metal corre el riesgo de puntos débiles. Las juntas roscadas fallan bajo presión. Los adaptadores de brida resuelven esto. Agarran el extremo de HDPE liso en un lado, perno a engranaje rebordeado en el otro. Si se hace bien, la reparación dura décadas.

Comprender los adaptadores de brida en sistemas HDPE

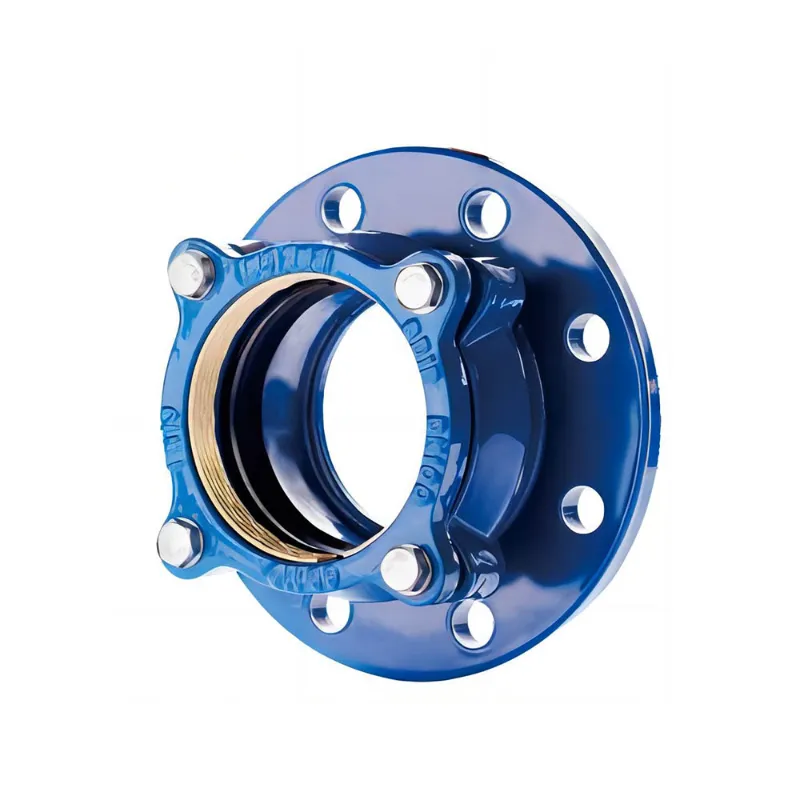

Adaptadores de brida conectar el extremo plano de una tubería de HDPE a equipos con bridas como válvulas, bombas, medidores de flujo o tuberías de acero antiguas. Hacen que estos enlaces sean seguros y a prueba de fugas.

Estos adaptadores incluyen un extremo de brida, un extremo de manguito, un anillo de sellado, un anillo de compresión y pernos. Cada parte juega un papel en mantener todo apretado.

Piense en cómo la manga agarra la tubería de HDPE mientras que la brida se atornilla hacia el otro lado. Simple, pero eficaz para materiales mixtos.

Por qué los acoplamientos estándar no siempre funcionan para reparaciones

Los acoplamientos mecánicos estándar brillan para conexiones de PE a PE del mismo material. Se deslizan fácilmente y sellan bien en esos casos. Los adaptadores de brida manejan mejor diferentes materiales o extremos de equipo. Puentan el HDPE con el metal sin problemas.

Los problemas surgen con materiales incompatibles. El sellado falla a veces. El espacio se apreta en los puntos de reparación. Las pruebas de campo muestran que los adaptadores Conflex pueden conectar HDPE a bridas metálicas sin soldadura adicional o modificación de rosca, lo que reduce el tiempo de inactividad. Eso’ es un ahorro de tiempo real en el trabajo.

¿Alguna vez ha tratado con una articulación con fugas de prisa? Elegir el conector equivocado solo arrastra las cosas.

Factores clave a considerar al elegir un adaptador de brida

1. Diámetro de la tubería y rango de compatibilidad

Coincide con el adaptador’ Tamaño del tubo’ diámetro exterior. Los rangos comunes van de DN50 a DN600.

Observe las diferencias estándar como ISO4427 frente a ASTM D3035. Afectan el ajuste.

Conflexar Los adaptadores cubren las gamas DN50 a DN600, lo que los hace adecuados para la mayoría de los escenarios de reparación de HDPE. Práctico para proyectos variados.

2. Clasificación de presión y condiciones de trabajo

PN10 se adapta a presiones más bajas, bueno para la distribución de agua. El PN16 maneja cargas más altas, como en configuraciones industriales.

Algunos adaptadores soportan una presión de sellado de hasta 2,5 MPa. Revisa el sitio’ las demandas.

¿Condiciones duras? Factor en fluctuaciones de temperatura o productos químicos. Todo se relaciona con la tolerancia a la presión.

3. Selección de material y recubrimiento

El hierro dúctil GG50 forma el cuerpo para obtener fuerza. Anillos de sellado de EPDM o NBR proporcionan flexibilidad. Acero inoxidable o pernos recubiertos resisten la oxidación. Los recubrimientos importan mucho.

Enfócate en la resistencia a la corrosión, especialmente en lugares difíciles. Para el agua potable, busque la aprobación de WRAS para mantener las cosas seguras.

Hechos de hierro dúctil GG50 con revestimiento epoxi unido a fusión, los adaptadores Conflex resisten a la corrosión incluso en entornos de aguas residuales. probado en el campo.

4. Acceso al entorno de instalación y mantenimiento

Las trincheras subterráneas o los agujeros apretados limitan los movimientos. Elija diseños de cuerpo ajustables o cortos para facilitar el trabajo. Estos reducen la excavación o herramientas adicionales. El mantenimiento también es más sencillo.

La estructura compacta de Conflex Adaptadores de brida ajustables lo hace ideal para pozos de reparación confinados. No más lucha en espacios estrechos. A veces, un poco de ajustabilidad ahorra horas. Vale la pena señalar al planificar.

Paso a paso: Reparación de una tubería de HDPE con un adaptador de brida

La reparación de las líneas de HDPE sigue pasos claros. Comience sencillo.

- Corta la sección dañada. Usa una sierra para limpiar los bordes.

- Limpia los extremos de la tubería y mide los diámetros. La suciedad arruina los sellos.

- Montar el anillo de sellado y el adaptador de brida. Deslizalo con cuidado.

- Ajuste los pernos uniformemente en un patrón diagonal. Evite exagerar un lado.

- Realice una prueba de presión. Cuidado con las fugas.

Estos pasos mantienen las cosas sencillas. Salta uno, y los problemas siguen. Herramientas como llaves de par ayudan con pernos. Compruebe siempre las mediciones.

Errores comunes en la selección del adaptador de brida

Las discrepancias de tamaño ocurren a menudo. Los estándares EN1092 y ANSI difieren, lo que conduce a ajustes deficientes. El torque del perno también va mal. Demasiadas grietas partes; Demasiado poco causa fugas.

¿Olvidar la expansión térmica? Las tuberías se hinchan en el calor, se contraen en el frío. Los adaptadores deben permitirlo. ¿Has visto trabajos donde una solución rápida se convirtió en una refacción? Por lo general de estos resbalones.

Planifica por adelantado. Medir dos veces.

Ejemplo de caso – Restauración de una línea de agua municipal

Imagine una tubería DN200 HDPE estallando en un sistema de agua de la ciudad. El agua salía, las calles inundaban. Las tripulaciones cortaron la sección mala rápidamente. Se agarran a un adaptador de brida ajustable para conectar el HDPE a una nueva válvula.

La instalación dura menos de una hora. El agua fluye de nuevo, interrupción mínima. La característica ajustable maneja ligeros desalineamientos. Recuperación rápida para la comunidad.

Las soluciones del mundo real como esta destacan opciones inteligentes. El tiempo de inactividad disminuye, los costos se mantienen bajos.

Pensamientos finales: Soluciones fiables para reparaciones duraderas

Los adaptadores de brida derecha prolongan la vida útil de la tubería y reducen las facturas de mantenimiento. Se sellan bien, aguanta. Preste atención a los estándares, materiales y poder de sellado. Paga a largo plazo.

En el trabajo de tuberías, los detalles importan. Una adaptador sólido convierte un parche en una solución permanente. ¿Alguna vez has notado cómo los componentes pequeños hacen grandes diferencias? Eso’ El juego aquí. Elija sabiamente, y el sistema funciona sin problemas durante años.

¿No estás seguro de qué adaptador se adapta a tu proyecto de reparación de HDPE?

Hable con el equipo técnico de Conflex para obtener asesoramiento experto en selección.

Preguntas frecuentes

P: ¿Cómo conectar una tubería de HDPE a una brida?

Corta el cuadrado de la tubería, limpia el extremo, desliza el anillo de sellado, empuja el manguito del adaptador de brida sobre la tubería, y luego atornilla la cara de brida a la brida de acoplamiento en un patrón de estrella. Torque a especificaciones y prueba de presión.

P: ¿Cuáles son los diferentes tipos de adaptadores de brida?

- Adaptadores de brida fija – de una sola pieza, longitud fijada.

- Adaptadores de brida ajustables – Manga telescópica para ±25 mm de juego.

- Adaptadores de brida restringidos – anillos de agarre para detener la extracción bajo empuje.

P: ¿Cuál es la diferencia entre un adaptador de acoplamiento y un adaptador de brida?

Un acoplamiento une dos tuberías de extremo plano (PE-PE o PE-metal). Un adaptador de brida une un tubo de HDPE de extremo plano a una válvula, bomba o tubo de acero con brida.

P: ¿Cómo se relaciona el tamaño de la tubería con el tamaño de la brida?

Tamaño del tubo = diámetro exterior (por ejemplo, DN200 = 200 mm de diámetro exterior). El tamaño de la brida sigue las normas de patrón de perno (EN1092 PN16, ANSI 150). DN200 HDPE típicamente se empareja con una brida DN200, pero siempre confirme la tolerancia OD y la coincidencia estándar.