PE (polietilen) borularını klapanlara, axın ölçücülərinə və ya metal boru kəmərlərinə bağlamaq üçün flanç adapterləri vacibdir. Düzgün quraşdırıldıqda möhkəm, su keçirməz bir bağlantı təmin edirlər. Lakin zəif bir quruluş sızıntılara, bahalı gecikmələrə və ya hətta sistem pozulmalarına səbəb ola bilər. Heç kim səhər saat 2-də daşqın içində olmaq istəmir.

Bu təlimat quraşdırıldıqda ən tez-tez beş sürüşməni əhatə edir Фланец-адаптерлер PE boruları üçün. Onlardan qaçmaq üçün praktik məsləhətlər də verir. İstər mühəndis, istərsə podratçı, istərsə də texnik olsanız, bu göstəricilər işdə vaxt və pul qənaət etməyə kömək edəcəkdir.

PE Boruları üçün Flange Adaptor nədir?

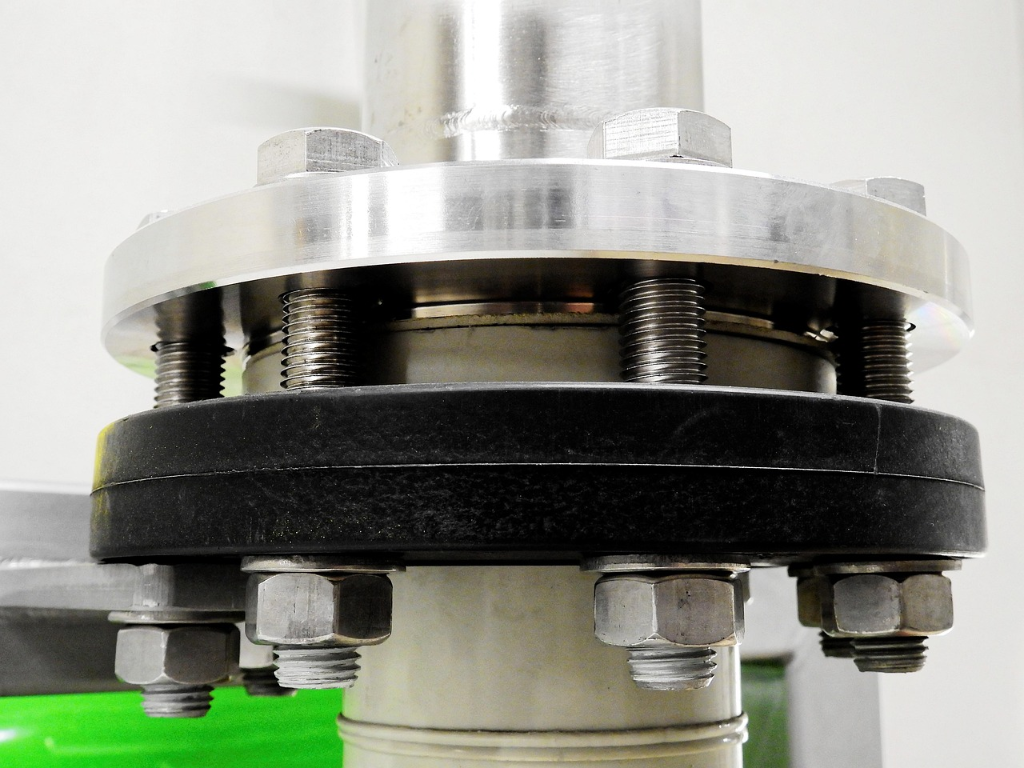

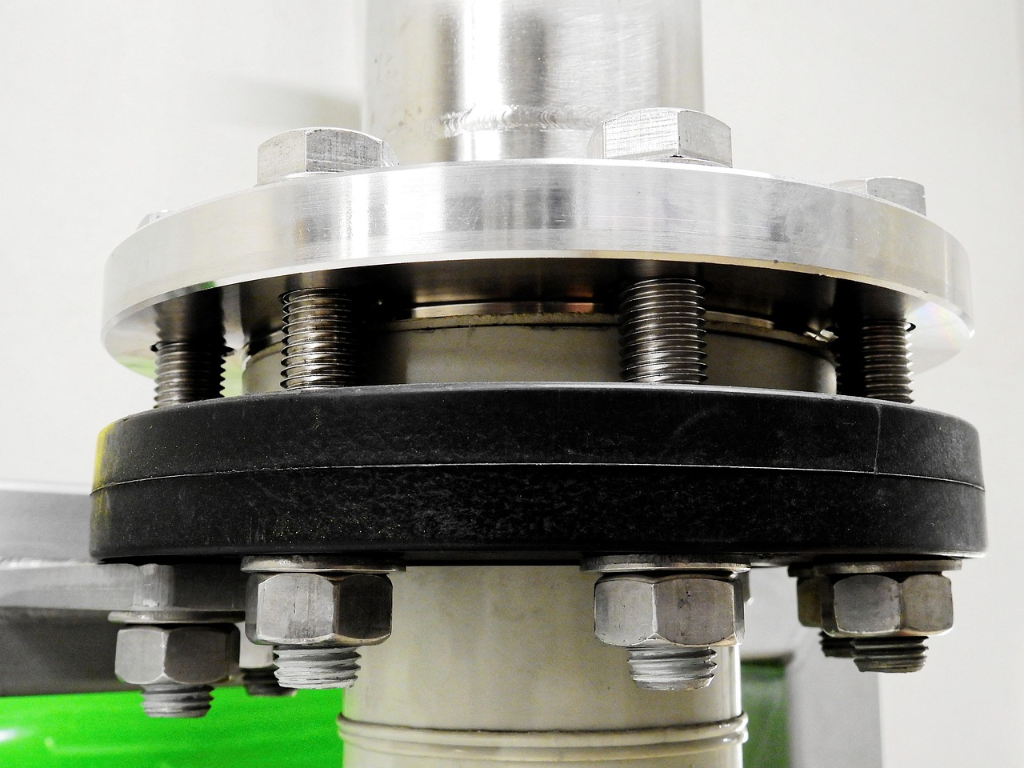

Bir flanç adapteri PE borularını klapanlar, nasoslar və ya təzyiq ölçücüləri kimi avadanlıqlara qoşur. Bükülə bilən plastik borular və sərt metal sistemlər arasında möhkəm bir əlaqə kimi xidmət edir. Əsas hissələrə aşağıdakılar daxildir:

| Бөлшек аты | Material Seçimləri | Standart istinad |

|---|---|---|

| Фланецтік құбыр | GGG50 Dəmir | EN1563 |

| Резеңке тығыздағыш | EPDM, SBR və ya NBR | ISO4633 |

| Без фланеці | GGG50 Dəmir | EN1563 |

| БОЛСТАР ЖӘНЕ БАСҚА | Karbon polad və ya paslanmayan | ISO898 |

| Аяқтау қабаты | Fusion Bond Epoxy | EN14901 |

Möhürləmə sistemi tez-tez bir güvercin quruluşu kauçuk üzükdən istifadə edir. Doğru quraşdırıldıqda sıx bir möhür yaradır. İçməli su, kanalizasiya və neytral maye üçün ideal olan 2,5 MPa-ya qədər təzyiqləri idarə edə bilər.

1. Boltlarda səhv tork

Böyük bir səhv boltları qeyri-bərabər və ya səhv qüvvə ilə sıxmaqdır. Bəzi boltlar çox sıx, digərləri isə çox boşaldıqda, sızdırma bərabər şəkildə aşağı basmayacaq. Bu, sistem təzyiq altında olduqda sızıntılara səbəb ola bilər.

Nümunə

DN300 boru kəmərini işləyən bir müqaviləçi, başladıqdan cəmi iki gün sonra sızıntı yaşadı. Problem? Bəzi boltlar zərbə açarı ilə işləyirdi, digərləri isə əllə çətinliklə sıxılmışdı.

Ondan necə qaçınmaq olar

- Düzgün yoxlanılmış bir tork açarından istifadə edin.

- Avtomobil təkərləri ilə olduğunuz kimi, vidaları çapraz bir nümunədə sıxın.

- PN10 və ya PN16 təzyiq dərəcələri üçün istehsalçının tork qaydalarına riayət edin.

2. Kauçuk Sigletin səhv yerləşdirilməsi

Qatlar sadə görünür, lakin yerləşdirilməsi vacibdir. Əgər möhürləmə üzüyü göyərlin quyruğu çuxuruna doğru qoyulmazsa, hətta kiçik bir dəyişiklik də boşluqlar buraxa bilər.

Tipik məsələ

Quraşdırma zamanı kimsə qapağı düşür və bir parça ilə silir. Bu yaxşı görünür, amma kir ona yapışsa, möhür düz oturmayacaq. Zamanla kiçik bir damla başlaya bilər.

Ondan necə qaçınmaq olar

- Montajdan əvvəl oyuq və sızdırma yaxşı təmizləyin.

- Səhifənin heç bir bükülmədən çuxura sıx uyğunlaşdığından əmin olun.

- Köhnə qatları yenidən istifadə etməyin; Sıxıldıqdan sonra formalarını itirirlər.

3. Boru tənzimlənməsini görməzlikdən gəlmək

Flans adapterləri faydalıdır, lakin pis uyğunluğu düzəldə bilməzlər. PE borusu bolt edildikdə mərkəzdən çıxırsa, birləşmədə gərginlik yığılır. Bu stres zaman keçdikcə əlaqəni qırır və ya boşaltır.

Bu necə olur

Təsəvvür edin ki, bir boru sıx uzanıb bir çubuq üzərində və yerinə məcbur olunur. Flanç üzləri bir az bucaqda görüşür, bəlkə də yalnız 2 və ya 3 dərəcə uzaqlıqda. Lakin aylarla titrəmədən sonra bir sızıntı görünür.

Qarşısının alınması üçün məsləhətlər

- Boruları qatlamağa başlamazdan əvvəl düzəldin.

- Borudan gərginliyi aradan qaldırmaq üçün dəstəklər və ya jacks istifadə edin.

- Flanç üzlərində düz bir kənarla uyğunluğu yoxlayın.

4. Səth qorunması atlamaq

Bir çox işçi düzgün örtüklərə ehtiyacını görməzlikdən gəlir. Yaxşı bir örtük olmadan su, kimyəvi maddələr və ya kanalizasiya sularına məruz qalan bir flanç adapteri, boltlar paslanmayan poladdan olsa da, paslana bilər.

Niyə vacibdir

Paslanma, qurulan dəmir bədənini zəifləyir, bağlantıyı daha az təhlükəsiz edir. Pis hallarda təzyiq altında tam uğursuzluğa səbəb ola bilər.

Nə etməliyik

- Fusion bond epoxy və ya oxşar bir örtük olan adapterləri seçin.

- Quraşdırma zamanı örtüyü çizməməyə diqqət yetirin.

- Təsdiq edilmiş təmir boyası ilə hər hansı bir çizişə toxunun.

5. Temperatur və təzyiq hədlərini nəzərdən keçirmək

PE boruları üçün flanç adapterləri PN10 və ya PN16 təzyiqləri və temperaturları üçün -10 ° C-dən 70 ° C-ə qədər hazırlanmışdır. Bu məhdudiyyətlərin ötürülməsi problemlərə səbəb olur.

Nümunə

Bir layihədə 90 ° C yaxınlığında çalışan isti su sistemində adapter istifadə edildi. Qapaq tez aşındı və birləşmə cəmi altı ay ərzində uğursuz oldu.

Ondan necə qaçınmaq olar

- Həmişə təzyiq sinifini yoxlayın (PN10 vs PN16).

- Sistemi tövsiyə olunan temperatur aralığında saxlayın.

- Taşınan mayəyə uyğun olan sıxışdırıcıları (EPDM, SBR, NBR) seçin.

Conflex буындары туралы

Conflex буындары Boru kəmərinin bağlanması və təmir məhsulları, məsələn, flanç adapterləri, birləşmələr və təmir klempləri hazırlamaqda ixtisaslaşmışdır. Onlar həmçinin xüsusi layihə ehtiyacları üçün xüsusi həllər təklif edirlər.

Məsələn, flanç adapterlərindən başqa, Conflex Joints təklifləri çevik birləşmələr və PE borularını klapanlara və ya nasoslara bağlamaq kimi oxşar vəzifələr üçün birləşmələrin sökülməsi. Bu əşyalar möhkəmdir və korroziyaya yaxşı dayanır, buna görə də şəhər su və kanalizasiya sistemləri üçün əla seçimdir.

hamar quraşdırma üçün praktik məsləhətlər

Burada saytda istifadə üçün sürətli bir yoxlama siyahısı:

- Adaptoru seçməzdən əvvəl boru diametrini (DN50DN600) yoxlayın.

- Bütün möhürləmə üzüklərini kir və ya zərər üçün yoxlayın.

- Doğru torkdan istifadə edin və çapraz bir nümunədə sıxın.

- Son sıxılmadan əvvəl tənzimlənməni iki dəfə yoxlayın.

- Gələcək istinad üçün quraşdırma detallarını yazın.

Қорытынды

Qeydiyyat PE borular üçün flange adapterləri olduqca sadədir, amma kiçik sürüşmələr böyük baş ağrılarına səbəb ola bilər. İstər bolt sıxılığını düzgün əldə etmək olsun, istərsə də sıxılmanı düzgün yerləşdirmək olsun, hər kiçik az sayılır. Bu beş tez-tez səhvdən qaçmaqla, podratçılar və mühəndislər sızıntıları və sistem uğursuzluqlarını aradan qaldıra bilərlər.

Etibarlı bağlantı seçimləri axtaran hər kəs üçün Conflex Joints su, kanalizasiya və sənaye işlərində möhkəm bir təcrübəsi olan ən yüksək səviyyəli məhsullar təmin edir.

ЖҚС

Q1: PE boruları üçün flanç adapterləri quraşdırarkən ən böyük səhv nədir?

Ən çox yayılmış problem səhv bolt torkudur. Qeyri-bərabər sıxılma sızıntılara səbəb olur, çünki sızıntı düzgün aşağı basmır.

Q2: PE boruları üçün flanç adapterləri yüksək təzyiqi idarə edə bilərmi?

Bəli, əksəriyyəti PN10 və PN16 sistemləri üçün nəzərdə tutulmuşdur, düzgün quraşdırıldıqda 2,5 MPa-ya qədər möhürlənir.

S3: Bir flanç adapterini yenidən quraşdırdığım hər dəfə kauçuk sızdırma dəyişdirməliyəmmi?

Bəli. Basıldıqdan sonra qapaq uzantısını itirir. Onun yenidən istifadəsi tez-tez sızıntılara səbəb olur.

Q4: PE boruları üçün flanç adapterinin hansı örtük növünə sahib olmalıdır?

Fusion bond epoksi örtüyü geniş istifadə olunur, çünki içməli su və kanalizasiya mühitlərində pasla mübarizə aparır.

S5: Flanç adapterlərini quraşdırarkən səhv uyğunluqdan necə qaçına bilərəm?

PE boru bolt əvvəl yaxşı dəstəkləyin. Flanç üzlərinin bərabər olub olmadığını yoxlamaq üçün düz bir kənardan istifadə edin.