Advantages of Ductile Iron Piping Systems

Key Benefits of Using Ductile Iron Pipes in Industrial Applications

Ductile iron pipes shine in industrial projects. They’re tough and bendable. These pipes can manage high pressure with ease. They’re perfect for carrying water, gas, or other fluids across long stretches. Shocks and vibrations? No problem. They stay strong during earthquakes or under heavy traffic. This strength means less fixing and a longer life.

Rust is no match for these pipes. Unlike old cast iron, ductile iron pipes have special coatings. These stop corrosion in its tracks. They hold up in harsh soils or salty areas. Plus, ductile iron pipe dimensions come in many sizes. This lets engineers craft solutions that fit specific needs, making them useful in all sorts of industries.

Durability and Longevity of Ductile Iron Pipe Dimensions

Ductile iron pipes are built to last. They mix tiny graphite bits with a sturdy structure. This combo gives them incredible strength without losing flexibility. They can take heavy stress and not crack.

With the right setup and care, these pipes can keep going for 100 years or more. Standard ductile iron pipe dimensions make them easy to pair with fittings and parts used in pipelines. This ensures they stay reliable for the long haul.

Environmental Benefits of Ductile Iron Piping Systems

These pipes are kind to the planet. They’re made from recycled stuff, which cuts down on using new materials. Less waste is a big win. When they’re done serving, they can be recycled again. This keeps resources cycling.

Their smooth insides reduce drag when fluids flow. That means pumps use less energy. Lower energy use saves money and cuts emissions that harm the environment. These perks make ductile iron pipes a smart, green pick.

Installation Best Practices for Ductile Iron Piping Systems

Preparation Steps for Installing Ductile Iron Pipes

Good prep sets the stage for installing ductile iron pipes. First, check the site carefully. Look out for tricky soil, buried utilities, or obstacles. Make sure pipes and fittings meet the required specs.

Dig trenches to the proper depth and width for ductile iron pipe dimensions. Clear the trench bottom of rocks or sharp bits that could nick the pipe’s coating. Lay down sand or gravel to give the pipe steady support.

Proper Techniques for Joining and Connecting Ductile Iron Pipes

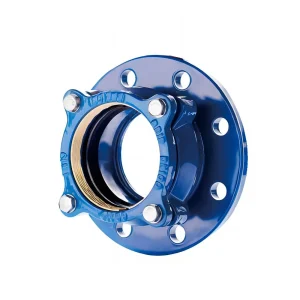

Joining these pipes takes skill to keep leaks away. One solid method is push-on joints. These use rubber gaskets that seal tight when one pipe slides into another. Mechanical joints work too. They bolt together with gaskets for extra security.

For unique projects, Qopqoq bo'g'inlari Customization Service offers made-to-order products. These tackle specific pipeline issues with ease. After joining, check each connection. Ensure it’s lined up right and sealed tight before filling the trench.

Tips to Ensure Efficient Installation and Minimize Downtime

Smart planning keeps installation smooth and downtime low. Use tools like hydraulic cutters or trenchless tech, such as horizontal directional drilling (HDD), for precise work. Train workers to move and place pipes without damage. Have a backup plan for surprises like bad weather or broken tools. Check progress often to spot issues early. Keep in touch with everyone on the project to make decisions fast. These steps help install ductile iron piping systems quickly and well.

Common Applications of Ductile Iron Piping Systems

Use of Ductile Iron Pipes in Water Supply and Drainage Systems

Ductile iron pipes are a go-to for water and drainage systems. Their strength, durability, and rust resistance make them stand out. They handle high-pressure water flow, delivering it to cities or rural spots without fail. Their tough build resists pressure from soil or traffic, ideal for underground setups.

The smooth inner surface cuts down on friction. This boosts water flow and saves energy. It ensures steady delivery over long distances. Standard ductile iron pipe dimensions fit easily with fittings and parts, blending into existing systems.

For drainage, these pipes resist chemical damage. They carry wastewater or harsh liquids without trouble. Protective coatings help them last in tough soils or salty conditions.

Application in Heating, Gas, and Oil Distribution Networks

Ductile iron pipes are great for heating systems. They carry heat well and handle high temperatures. This makes them perfect for moving hot water or steam in homes, businesses, or factories. Their strong structure stays solid under heat stress.

In gas networks, these pipes are safe and steady. They transport natural gas without cracking. Their flexibility handles outside forces. Tight joints, like push-on or mechanical ones, stop leaks, keeping things safe.

The oil industry counts on ductile iron pipes for moving crude oil or refined products. They resist wear from gritty materials like oil with sediment. Ductile iron pipe dimensions allow custom setups for oil networks.

Role of Ductile Iron Pipe Dimensions in Chemical Industry Operations

The chemical industry needs pipes that can handle tough substances. Ductile iron pipes are up to the task. They’re strong, flexible, and resist chemical damage. Their graphite bits add toughness and handle stress without breaking.

Standard ductile iron pipe dimensions make designing chemical pipelines simple. They work with valves, flanges, and other parts in factories. This makes maintenance and replacements easier.

These pipes come with linings like epoxy or cement mortar. These shield against harsh chemicals or extreme pH levels. This keeps them going strong in chemical plants.

Tez-tez beriladigan savollar (FAQ)

What makes ductile iron pipes suitable for water supply systems?

They’re strong, durable, and resist rust. Their smooth insides improve water flow, making them perfect for water systems.

Can ductile iron pipes be used in high-temperature applications?

Yes, they handle heat well. Their strength and heat conductivity make them great for heating systems.

Are ductile iron pipe dimensions standardized?

Yes, standard sizes ensure they work with pipeline parts across industries.

How do ductile iron pipes perform in chemically aggressive environments?

They do well thanks to their toughness and linings like epoxy or cement mortar. These protect against harsh chemicals.

Where can I find products compatible with ductile iron piping systems?

Qopqoq bo'g'inlari provides specialized products for connecting and repairing pipelines. They match standard ductile iron pipe dimensions. Reach out for custom solutions for global pipeline needs!