Running a water supply system is never simple. Pipes wear down. Valves break. Leaks show up when you least expect them. One failure can affect entire neighborhoods. That is why engineers keep looking for ways to make maintenance faster and less painful. One part that helps a lot is the dismantling joint. This small piece makes it easier to take pipelines apart and put them back together. The result: less downtime, fewer problems, and smoother repairs.

If you want professional support, Conflex Joints is a trusted name. They focus on pipeline connection systems and have years of industry experience. Their products are made for water supply and industrial projects around the world.

According to their about page, Conflex specializes in flexible and safe connections that stand up to tough conditions. They don’t just sell you a part, they also provide consultation and technical advice. That way you can choose the right joint for your system. You can also reach them directly through their contact page. With their help, your system is likely to run longer and cost less to maintain.

Why Is Easy Installation and Disassembly Important in Water Supply Systems?

Time matters when a section of pipe or a valve needs fixing. Traditional methods often need welding or even cutting. That slows everything down. Dismantling joints solve this. You don’t need special tools. You don’t need days of shutdown. Instead, you just loosen bolts, adjust the joint, and finish the job.

Faster Pipe Adjustments During Maintenance

In practice, this makes a huge difference. A utility crew can swap out a valve or install a flow meter in hours instead of waiting days. Because the joint has adjustable length, it gives you space to pull out the old part safely. Then, when you reassemble, the alignment is easier. That means fewer leaks later.

Saving Labor Costs and Reducing Downtime

Downtime is expensive. Every hour without water service can affect thousands of people. By cutting repair time, dismantling joints reduce labor costs and prevent long service breaks. That is why many municipal networks now see them as essential parts of the system.

How Do Dismantling Joints Prevent Leaks?

Leaks are costly in every way. Treated water gets wasted. Operating costs rise. Sometimes, even nearby infrastructure is damaged. Dismantling joints fight leaks with gaskets. These can be EPDM, SBR, or NBR rubber. The gasket forms a secure seal between flanges.

Strong Sealing Performance

When bolts are tightened, the gasket becomes a barrier. It keeps water inside even under high pressure. That means fewer emergency repairs. For drinking water, WRAS approved gaskets are used so the water remains safe.

Protection Against Environmental Stress

Pipes are rarely still. Soil shifts. Pumps cause vibration. Temperature swings change pipe length. A dismantling joint can take these small movements without breaking the seal. That prevents tiny leaks from turning into big problems over time.

What Role Does Flexibility Play in Water Networks?

Pipelines are dynamic systems. They expand in heat, shrink in cold, and shift with ground movement. Rigid connections can’t handle that stress. Dismantling joints add flexibility and make the network more resilient.

Absorbing Vibrations and Reducing Stress

In pumping stations, dismantling joints act almost like shock absorbers. They stop vibration from traveling into the pipes. This not only protects the pipeline but also reduces wear on pumps and connected machines. The whole system lasts longer.

Enabling System Expansion and Modifications

Cities grow. Demand rises. At some point, a water network will need to expand. With dismantling joints in place, new sections can be added easily. Crews don’t need to remove long stretches of pipe. They just adjust the joint and connect the new piece.

How Do Dismantling Joints Improve Safety and Reliability?

Safety is always first in water projects. A dismantling joint, if installed correctly, reduces the risk of sudden failures. That means safer delivery and more reliable service.

Compatibility With Different Pipe Materials

It doesn’t matter if the pipeline is steel, ductile iron, or PVC. Dismantling joints are designed to work with all of them. That makes them suitable for new builds as well as upgrades of older systems.

Tested and Certified Performance

Many joints are built to international standards. EN1092-1 covers flange drilling. EN12266-1 covers pressure testing. To fight corrosion, some use fusion bond epoxy coatings. That makes them reliable for potable water, sewage, and even seawater.

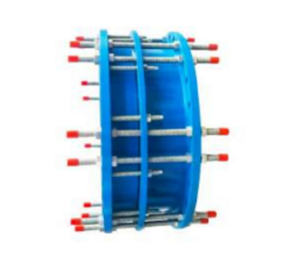

If your project needs robust options, you might look at products like the Steel Dismantling Joint VSSJA CF and VSSJA C2F. These handle a wide pressure range and work in environments from drinking water to sewage to seawater.

How Do Dismantling Joints Contribute to Cost Savings?

Budgets are tight in every project. The good news is dismantling joints save money in several ways.

Lower Lifetime Costs

Buying a dismantling joint is not expensive compared to the long term benefits. By preventing leaks, cutting downtime, and extending pipeline life, they lower the overall cost of running a water network.

Avoiding Emergency Repairs

Emergency failures are the worst. They cost more in labor, waste water, and cause service breaks. With dismantling joints, maintenance can be planned and predictable. That reduces surprise failures and saves money.

FAQ

Q1: What is the main function of a dismantling joint in water supply systems?

A: It gives an adjustable connection, making installation and maintenance much easier.

Q2: Can dismantling joints handle high pressure?

A: Yes. Many are rated for PN10, PN16, PN25, or even PN40.

Q3: Do dismantling joints work with all pipe materials?

A: Yes. They fit steel, ductile iron, plastic, and other common pipe types.

Q4: How do dismantling joints help reduce leaks?

A: By using quality gaskets that seal tightly and absorb small movements.

Q5: Are dismantling joints cost effective for large projects?

A: Definitely. They save on labor, reduce downtime, and cut the risk of emergencies, making them worth the cost.