Understanding Flange Adaptors and Their Purpose

What Are Flange Adaptors?

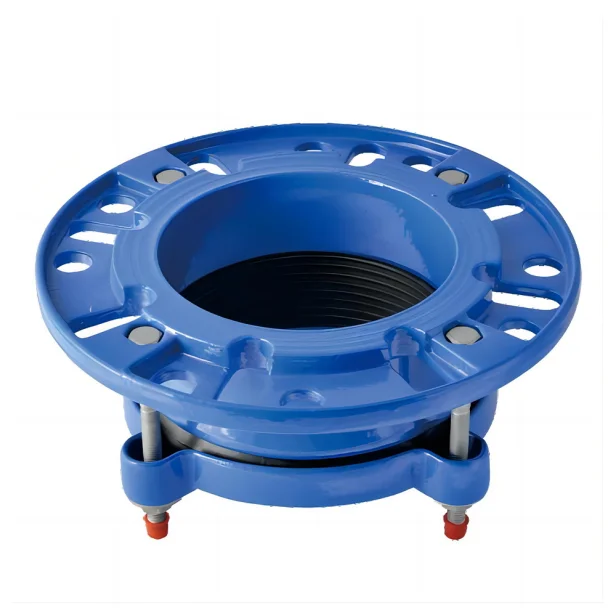

Flange adaptors are important pieces in pipeline systems. They connect pipes made of different materials or sizes. Think of them as a bridge that joins pipes tightly. They stop leaks and make connections strong. Many industries rely on them. These include water supply, gas distribution, and chemical processing. Their ability to work in many situations makes them a key part of modern pipelines.

Key Features of Flange Adaptors in Pipeline Systems

Flange adaptors are built to be tough and flexible. They’re often made from materials like ductile iron or stainless steel. These materials can handle high pressure and rough conditions. They don’t rust easily, so they last a long time. Installing them is simple. They work with all kinds of pipes. Plus, flange adaptors have gaskets or sealing rings. These ensure a tight connection, even when things get tough.

The Functionality of Dismantling Joints in Pipeline Systems

What Is a Dismantling Joint?

A dismantling joint is a special tool for pipelines. It helps put pipeline sections together or take them apart. It’s made of several parts. These parts let you adjust the pipe’s length a little. This makes it easy to remove things like valves or pumps during repairs. Dismantling joints save time and money. They make it simpler to reach important pipeline parts.

How Dismantling Joints Facilitate Maintenance and Repairs

Dismantling joints make pipelines more flexible. They let you make small tweaks during setup or maintenance. Need to fix or replace a valve or pump? Just loosen the dismantling joint. This creates space to take out the equipment. It doesn’t mess with nearby pipeline sections. This saves time. It also reduces the chance of breaking other parts.

The Connection Between Dismantling Joints and Flange Adaptors

Flange adaptors and dismantling joints work as a team. They make each other better. Dismantling joints give flexibility and allow adjustments. Flange adaptors create a solid connection between different pipe sections. Together, they solve problems in complex pipeline systems. They handle small alignment issues. They also make setup quicker and easier.

Advantages of Using Flange Adaptors in Dismantling Joints

Enhanced Flexibility and Adjustability in Pipeline Connections

One great thing about flange adaptors in dismantling joints is their flexibility. They can deal with pipes that aren’t perfectly lined up. This keeps the system steady and leak-free. This is super helpful in big industrial projects. Why? Because getting pipes to align perfectly can be really hard.

Simplifying Installation with Flange Adaptors

Flange adaptors make installation a breeze. They don’t need fancy tools or welding. Their design lets workers put them together fast. This cuts down on labor costs. It also shortens project timelines. This ease is a big deal when time is tight or when working in tricky spots.

Reducing Downtime During Maintenance

Flange adaptors and dismantling joints team up to save time during repairs. They let workers take apart and rebuild pipeline sections quickly. This means fewer interruptions to the system. For industries that need to keep running, this efficiency is a money-saver.

Applications of Dismantling Joints and Flange Adaptors Across Industries

Water Supply and Drainage Systems

Dismantling joints and flange adaptors are vital in water supply and drainage systems. They ensure pipes connect tightly with no leaks. Sometimes, pipes don’t line up perfectly during setup. These parts can handle that. Flange adaptors let you join pipes of different materials or sizes. This makes them a must-have in city water systems. Dismantling joints make maintenance easier. They let workers remove valves or pumps without touching nearby sections. This keeps downtime low in important water networks.

Heating and Gas Distribution Networks

In heating and gas systems, strong connections are everything. Flange adaptors make these systems tougher. They create seals that can handle high pressure and temperature changes. They resist rust, so they work well in harsh places like underground gas pipelines or industrial heating setups. Dismantling joints speed up repairs or upgrades. They cut down on disruptions. Together, these parts make energy networks safer and more efficient.

Oil and Chemical Pipelines

Oil and chemical industries need parts that can stand up to tough conditions. Think corrosive chemicals and changing pressures. Flange adaptors made from stainless steel or ductile iron are perfect. They’re strong and don’t get damaged by chemicals. Dismantling joints help with routine checks or urgent fixes. They make it easier to follow strict safety rules. Using these parts together keeps pipelines strong and improves maintenance plans.

Choosing the Right Flange Adaptor for Dismantling Joints

Factors to Consider When Selecting a Flange Adaptor

Picking the right flange adaptor takes some thought. The pipeline’s pressure and temperature matter a lot. These affect what material and design you need. The adaptor must also fit with other pipeline parts. This ensures a smooth connection. For high-pressure systems, flange adaptors might have stronger gaskets or extra sealing features. These stop leaks in tough conditions.

Material Compatibility and Durability Requirements

The material of a flange adaptor is a big deal. It decides how well it works and how long it lasts. Ductile iron is strong and flexible. It’s great for water supply systems. Stainless steel fights rust better. It’s ideal for chemical pipelines or places near saltwater. For harsh chemicals or high temperatures, special alloys might be needed to stay durable.

Ensuring Proper Fit and Alignment

A good fit and alignment are key for a leak-free connection. Misaligned pipes can weaken the system. This might cause leaks or breakdowns later. Flange adaptors help by allowing small tweaks during setup. To get the best results, choose flange adaptors that match the pipeline’s exact size and needs.

Frequently Asked Questions

What industries benefit most from using dismantling joints?

Dismantling joints are used in industries like water supply, gas distribution, oil refining, and chemical processing. They make maintenance tasks easier.

How do flange adaptors improve pipeline durability?

Flange adaptors create strong connections. They stop leaks and handle high-pressure conditions.

Can flange adaptors be customized for specific applications?

Yes, manufacturers like Conflex Joints offer customization. They meet special needs for industrial pipeline connections.

Are dismantling joints suitable for high-pressure pipelines?

Yes, dismantling joints work well in high-pressure systems. They perform best with parts like flange adaptors.

For more details on how Conflex Joints specializes in industrial pipeline solutions with over 15 years of expertise worldwide, reach out or check out their services!