Understanding the Basics of Dismantling Joints

Definition and Purpose of Dismantling Joints

Dismantling joints are special parts used in pipeline systems. They help make installing, fixing, and taking apart pipes easier. These joints let you remove or swap out valves, pumps, or other parts without messing up the whole system. Their main job is to give flexibility. They help line up parts during setup. They also make future fixes simpler.

Key Components of a Dismantling Joint

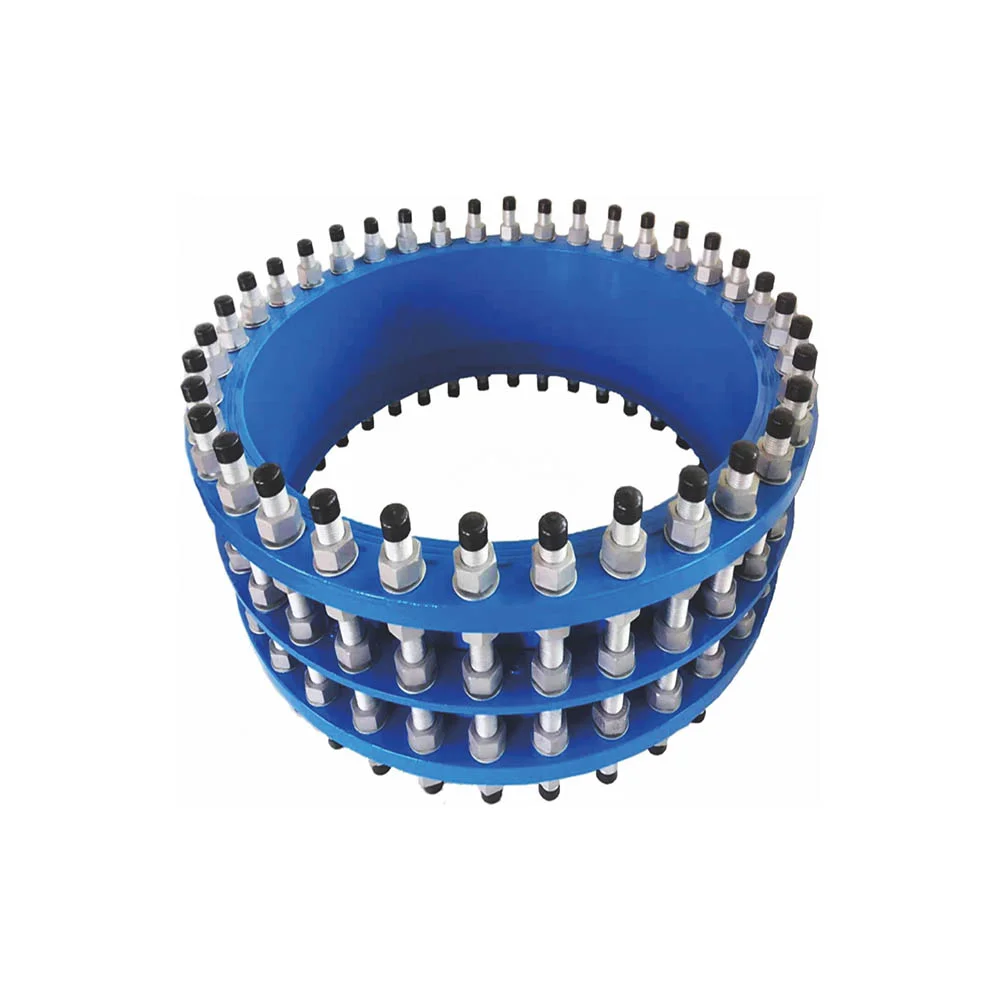

A dismantling joint has three main pieces. There’s the body, the dismantling flange adapter, and tie rods. The body is the middle part. It connects two pipe sections. The dismantling flange adapter makes a tight link to nearby equipment or pipes. Tie rods are super important. They keep everything strong by handling pressure forces. These parts team up to make a solid but adjustable connection.

Common Applications of Dismantling Joints in Industrial Pipelines

Dismantling joints are used a lot in different industries. You see them in water supply, sewage treatment, oil and gas, power plants, and chemical factories. They’re awesome when pipelines need regular checks or part swaps. For example, in water treatment plants, dismantling joints make it easy to take out pumps or valves for fixes. In oil refineries, they help quickly pull apart tricky pipe setups during routine checks or emergency repairs.

The Functionality and Benefits of Dismantling Joints

How Dismantling Joints Facilitate Pipeline Maintenance

Dismantling joints make pipeline fixes way easier. They let you adjust length and alignment. This means no need for lots of cutting or welding when swapping parts. It saves time. It also cuts down on worker costs. Plus, dismantling joints help position equipment just right during setup. This keeps things working well and lasting longer.

Advantages of Using Dismantling Joints in Engineering Projects

Dismantling joints bring lots of perks to projects:

Easy Setup: Their adjustable design fixes small lineup mistakes between pipe sections.

Saves Time: Quick setup and takedown make building and fixing faster.

Saves Money: Less worker time means lower costs over the project’s life.

Works Anywhere: They fit lots of jobs across different industries.

These benefits make dismantling joints a must-have in modern pipeline work.

The Role of Dismantling Flange in Ensuring Secure Connections

The dismantling flange is a key part of a dismantling joint. It makes sure pipes or equipment connect tightly. It gives a strong seal to stop leaks, even under high pressure. You can take it apart easily when needed. Tie rods add extra strength. They fight against pressure forces. This makes the dismantling flange super important for keeping the system safe and reliable.

Types and Variations of Dismantling Joints

Overview of Different Types of Dismantling Joints

Dismantling joints come in a few types for different jobs:

Single Flange Joints: Made for simple connections with little movement.

Double Flange Joints: Give more wiggle room for movement and slight angles.

Telescopic Joints: Let you adjust length a lot for heat expansion or shrinking.

Each type fits specific needs based on how the pipeline works.

Materials Commonly Used in Manufacturing Dismantling Joints

The stuff used to make dismantling joints depends on things like pressure, heat, and what’s flowing through the pipes. Common materials are:

Carbon Steel: Super strong and tough for everyday jobs.

Stainless Steel: Fights rust well for harsh places.

Ductile Iron: Strong but bendy, great for active systems.

Composite Materials: Light options for special needs.

These materials make sure dismantling joints work well in all kinds of conditions.

Selecting the Right Dismantling Joint for Specific Applications

Picking the best dismantling joint means thinking about a few things. Check the pipe size, pressure level, heat range, and what’s flowing inside. Make sure it works with other equipment too. Talking to makers who offer custom options can help. They can build solutions just for your project.

Installation and Maintenance of Dismantling Joints

Steps for Proper Installation of a Dismantling Joint

Installing dismantling joints right is super important. It keeps pipelines working well. Here’s how to do it:

Check and Prep: Look at all parts of the dismantling joint. Check the body, dismantling flange adapter, and tie rods. Make sure there’s no damage.

Line It Up: Match the joint with the pipe sections. It needs to fit just right. Bad alignment can cause problems.

Fasten It: Attach the dismantling flange adapter to the pipe or equipment. Use the right bolts. Tighten them evenly to avoid stress.

Add Tie Rods: Put tie rods in their holes. Tighten them the same way. They hold everything strong against pressure.

Test for Leaks: After setup, do a pressure test. Check for leaks or weak spots.

These steps make sure dismantling joints work great and stay trouble-free.

Tips for Maintaining and Extending the Lifespan of Dismantling Joints

Taking care of dismantling joints keeps them working longer. Here’s how:

Check Often: Look at joints now and then. Watch for wear, rust, or damage. Fix problems fast.

Lube Parts: Put grease on bolts and tie rods. This stops them from getting stuck.

Clean It: Wipe off dirt or chemical buildup. This prevents rust and keeps things working.

Tighten Bolts: Check bolts sometimes, especially after pressure changes. Keep them snug.

Swap Old Parts: If something’s worn out, replace it right away. This protects the whole system.

These simple steps make dismantling joints last longer. They also keep pipelines safe.

Troubleshooting Common Issues with Dismantling Flanges

Even with their strong design, dismantling flanges can have problems. Here’s how to fix common ones:

Leaks at Connections: Leaks often come from loose bolts or bad gaskets. Tighten bolts evenly. Replace gaskets if they’re worn.

Rust on Metal: Harsh places can cause rust. Use anti-rust coatings. Or pick materials that fight rust better.

Hard to Take Apart: Rust or dirt can make parts stick. Use oils to loosen them up.

Bad Realignment: When putting it back together, line it up right. Mark spots before taking it apart.

Fixing these issues quickly keeps the system strong. It also stops costly breaks.

The Importance of Quality in Manufacturing Dismantling Joints

Standards and Certifications for High-Quality Dismantling Joints

Top-notch dismantling joints follow strict rules to make sure they’re reliable:

ISO Standards: Many makers follow ISO rules. These ensure good quality control.

Material Rules: Materials must meet standards like ASTM or EN. This proves they’re strong and tough.

Pressure Tests: Joints get tested under tough conditions. This checks if they work well.

These certifications show dismantling joints are safe. They work great in hard jobs.

How Quality Impacts Performance and Durability in Industrial Pipelines

The quality of dismantling joints makes a big difference in how they work and last:

Super Reliable: Good materials fight wear, rust, and stress. They work well in all conditions.

Saves on Fixes: Tough parts need fewer repairs. This cuts costs over time.

Keeps Things Safe: Strong joints stop leaks or breaks in high-pressure systems.

Works Better: Well-made joints fit perfectly. They don’t waste energy from leaks or bad alignment.

Buying high-quality dismantling joints is key. It makes pipelines work better and saves money.

Frequently Asked Questions

What are dismantling joints used for?

Dismantling joints help with easy setup, fixes, and removal of pipeline parts like valves, pumps, or meters.

How can I maintain my dismantling joint effectively?

Check it often. Lube moving parts. Clean surfaces. Tighten bolts evenly. Replace worn bits.

What should I do if my dismantling flange leaks?

Look for loose bolts or bad gaskets. Tighten bolts the same way. Swap out gaskets if needed.

Why is quality important when selecting a dismantling joint?

Good quality makes joints reliable. It cuts repair costs. It keeps things safe. It makes pipelines work better.

For more information about Conflex Joints‘ expertise in manufacturing industrial pipeline products with guaranteed quality and efficient service globally across various industries over 15 years.