Pipeline projects are often costly. From the purchase of materials to the wages of workers, every step adds up quickly. That is why engineers and managers always search for ways to cut costs without losing quality. One simple but very effective way is through the use of flange adaptors. These fittings look simple, yet they provide faster installation, easier connections, and longer lasting performance.

In this article, we will explain how flange adaptors save money during both installation and the full service life of a pipeline. We will also highlight why choosing the right materials matters, drawing lessons from older pipelines and modern improvements.

Reduced Installation Time and Labor

Simple Assembly Compared to Welding

Traditional joints usually need welding. Welding means high heat, special tools, and skilled workers. It also takes a lot of time. By comparison, flange adaptors only need bolts and tightening. The job becomes much quicker. Workers spend less time on each pipe, and the project moves faster. This saves on labor and lowers overall costs.

Faster Pipeline Expansion and Connection

Pipelines often need to connect to existing systems. In such cases, shutting down the line for long welding work is very expensive. Adaptors make it easier. They connect new pipes in less time and with less disruption. Similar to dismantling joints, which adjust length for quick removal of valves, flange adaptors provide flexibility that reduces costly downtime.

Smaller Crew Requirements

Since the assembly is easier, fewer workers are required. Smaller teams mean lower labor bills and fewer safety risks. This is very important in projects where costs can rise quickly, such as municipal works or industrial sites.

Lower Material and Equipment Costs

Avoiding Specialized Welding Materials

Welding is not only slow, it also needs rods, gas, and inspection tools. These materials and equipment are expensive. Flange adaptors avoid this by using a simpler bolting method. The only tools needed are standard ones, which are cheaper and easier to keep.

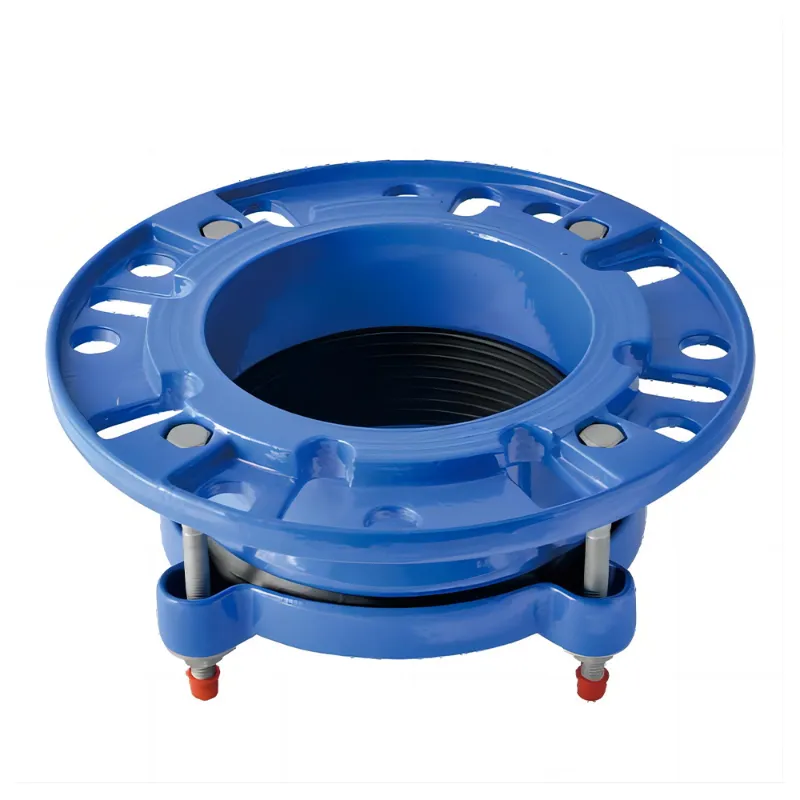

Compatibility with Multiple Pipe Materials

Modern systems use a mix of pipe materials: steel, ductile iron, or PE. Replacing whole sections because of mismatched ends can be very wasteful. A universal flange adaptor connects different pipe types with ease. This flexibility lowers waste and keeps costs under control.

Long Term Reusability

Another hidden saving is reuse. Many adaptors can be removed and used again. This is useful for temporary systems or projects that change often. Instead of buying new joints every time, the same adaptors can serve different stages of work.

Extended Service Life and Reduced Maintenance

Tight Sealing Reduces Leaks

Leaks are costly. They waste water or gas, damage the site, and require urgent repairs. Adaptors are made to seal tightly, which cuts the risk of leaks. This lowers maintenance costs and reduces unplanned shutdowns.

Resistance to Corrosion and Stress

The material of the adaptor makes a big difference. For example, ductile iron is stronger and more flexible than common cast iron. It can resist cracking and pressure swings. When adaptors include proper coatings and gaskets, they resist rust and wear for many years. That means fewer repairs and lower spending.

Simplified Inspection and Replacement

Every pipeline needs routine checks. Adaptors make inspection easy. If a part needs replacing, it can be done without removing large pipe sections. This simple process reduces the time and cost of maintenance work.

Indirect Cost Savings

Minimizing Project Delays

Project delays are expensive. They increase labor time, push back revenue, and may even lead to fines. Because flange adaptors allow quicker assembly and simpler expansion, they keep projects on schedule.

Lower Safety Risks on Site

Welding involves fire, burns, and toxic fumes. Flange adaptors reduce or remove such work. Fewer risks mean fewer accidents. That also lowers medical costs and insurance claims for the project.

Environmental and Energy Savings

Adaptors bring indirect savings for the environment too. Welding uses large amounts of energy, while bolting requires much less. Stronger seals also reduce leakage, which lowers the risk of fines for pollution or water damage.

Practical Applications Where Savings Are Significant

Municipal Water and Sewage Systems

Cities run very large pipe networks. Repairs and new connections must be done quickly to avoid service stops. Flange adaptors make it easier to connect old and new sections. This saves both time and money. They are especially useful when replacing aging pipes that show corrosion, low water pressure, or frequent leaks.

Industrial and Energy Projects

In power plants and factories, downtime is extremely costly. Adaptors give reliable joints that handle high pressure and stress. Using the right material, such as ductile iron with its toughness, further reduces risks and repair costs.

Desalination and Marine Pipelines

Pipes near the sea face heavy corrosion. Adaptors designed for PE or coated steel pipes reduce how often parts must be replaced. The flange adaptor for PE pipe provides a secure joint and resists chemical attack. This lowers maintenance costs in harsh environments.

Why Conflex Joints Matters in Cost Saving Solutions

Cost control in pipelines comes from both the product and the expertise behind it. Conflex Joints builds fittings that balance performance and savings. Their professional R&D team focuses on designs that reduce labor, shorten installation time, and cut repair needs.

With solutions like the universal flange adaptor and options built for PE pipes, they help engineers and contractors find fittings that reduce both upfront and long term costs. This practical approach turns smart design into real savings.

Conclusion: Value of Flange Adaptors in Cost Control

Pipeline projects are always tied to cost concerns. Flange adaptors help by reducing installation time, cutting material needs, and lowering maintenance. They also add safety and environmental benefits.

By combining smart fittings with durable materials, adaptors save money during both the start and the full life of a pipeline. For engineers, managers, and contractors who want both short term and long term savings, flange adaptors are a clear and proven choice. With the support of trusted makers like Qopqoq bo'g'inlari, these savings become even more reliable.

FAQ

Q1: How do flange adaptors cut costs compared to welding?

They avoid welding materials and tools, reduce labor hours, and speed up installation.

Q2: Can flange adaptors work in high pressure pipelines?

Yes. When chosen with the right pressure rating and material, they perform well in both water and industrial systems.

Q3: Are flange adaptors reusable?

Yes, many can be removed and reused in future jobs. This provides long term savings.

Q4: What kinds of pipes can be linked with flange adaptors?

They connect steel, ductile iron, and plastic pipes. This makes them very versatile.

Q5: How do they lower future maintenance costs?

By giving strong seals, reducing leaks, and making replacement easier, they cut expensive repair work.