Replacing Valves and Pumps on Rigid Pipelines

In pump rooms, valve chambers, booster stations, and water plant outlet lines, valves or pumps often need routine checks or swaps.

But with traditional rigid flanged connections, once the bolts come off, the valve gets stuck between two pipe sections. No room to pull it out. Workers end up cutting the pipe on site and welding in a new short piece. This drags out downtime, messes with water supply or production lines.

Space is tight, hoisting gets tricky, and safety risks climb. Nobody wants that headache. Steel dismantling joints step in here. They’re built to tackle these exact issues in valve replacement on flanged pipeline setups.

What Is a Steel Dismantling Joint and How Does It Work?

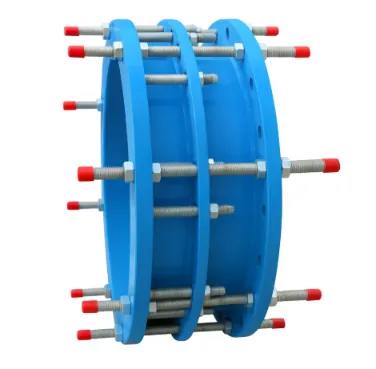

A steel dismantling joint has a double flanged body, a central sleeve or spigot, and tie rods holding it all together. It gives axial adjustable length, say 50 to 100 mm or more. That creates space for installing or removing parts.

The tie rods add restrained support. They lock against system pressure and water hammer, stopping axial shifts. Common builds use ductile iron or carbon steel with epoxy or FBE coating. Seals often go with EPDM or NBR.

Steel dismantling joints from Conflex typically offer an axial adjustment range of up to 100 mm and are supplied as fully restrained units for secure installation around valves and pumps.

Common Headaches When Replacing Flanged Valves or Pumps Without a Dismantling Joint

Pipelines stay too rigid. Can’t back out the valve or pump. Gotta cut the pipe. Then weld, which wrecks the coating and invites corrosion woes. Realigning flanges and matching holes? Tough. Often leads to poor seals.

Downtime stretches long. Construction risks spike. Replace flanged valve without dismantling joint. Not fun. Pump removal difficulties hit hard.

How Steel Dismantling Joints Simplify Valve and Pump Replacement

1. Creating the Extra Space You Need

Remove the tie rods or loosen bolts. The telescopic section shortens, freeing up 50 to 100 mm of gap. Valve or pump slides out easy. Or slips in. No cuts, no welds. Axial adjustment dismantling joint makes it happen.

Create installation gap for valves. Simple as that. Using axial adjustment of dismantling joints to remove valves saves the day.

2. Compensating for Construction Tolerances and Misalignment

That adjustable length handles build deviations, like civil works sizes or prefab pipe errors. When fitting a new valve or pump, tweak the length. Flange holes line up perfect. Dismantling joint for misalignment. Key fix.

Pipeline installation tolerance gets absorbed. How dismantling joints absorb pipework length tolerance around pumps? They flex just enough. Ever seen a site where measurements were off by a few mm? Happens all the time. These joints bridge that.

3. Providing Axial Restraint Against Thrust Forces

Pressure thrust and water hammer pull on valve or pump flanges. Tie rods clamp the setup between fixed points. No shifts, no leaks from thrust. Restrained dismantling joint. Essential.

Axial thrust control around valves keeps stability. Why use restrained dismantling joints on pump discharge lines? To fight those forces head-on.

4. Reducing Shutdown Time and Maintenance Cost

With a dismantling joint: Drain, unbolt, shorten the joint, hoist out the valve.

Without: Add cutting, welding, grinding, recoating, anticorrosion steps.

Value to operators? Shorter stops, less labor, fewer hoist hours. Reduce shutdown time with dismantling joint. Big win.

Maintenance cost saving follows. How dismantling joints reduce valve replacement downtime? By slashing steps.

In many retrofit projects, engineers report that using Conflex steel dismantling joints around critical valves has cut shutdown time for replacements from days to hours.

Where to Install Dismantling Joints Around Valves and Pumps

Picture this: One dismantling joint on each side of a valve. For pumps, before and after suction and discharge flanges. Around metering gear like flow meters or control valve groups, at both ends.

Single side or double? Depends. Tight spots might need one; full access, go double for max flex. Anchor and support properly. Don’t dump all pipe weight on the joint.

Where to use dismantling joint. Strategic spots. Dismantling joint location around valves. Flanks them. Best locations to install dismantling joints in a pump station? Near the action points.

Key Selection Criteria for Steel Dismantling Joints in Valve and Pump Chambers

Pipe size and flange standards: DN, PN, ANSI, AWWA. Pressure ratings like PN10, 16, 25, 40. Add safety margin.

Materials and corrosion protection: Ductile iron, carbon steel, stainless with epoxy or fusion bonded epoxy.

Adjustment range: Enough axial shift for install or remove needs.

Gasket materials: EPDM or NBR, matched to media like water, sewage, mild acids or alkalis.

How to select a dismantling joint. Match specs. Steel dismantling joint specifications guide choices. What size and pressure rating dismantling joint do I need for my valve? Check the line details.

Installation Best Practices and Common Mistakes

Steps: Clean pipe ends and flanges. Pre-assemble the joint. Adjust length. Tighten tie rods and flange bolts evenly. Pressure test.

Common slips: Setting adjustment backward, no spare room left.

Not tightening tie rods diagonally. Leads to uneven load, leaks. No supports or anchors. Joint bears too much weight.

Do: Torque bolts in crosses. Don’t: Rush the alignment.

Do: Check seals twice. Don’t: Skip the test.

Dismantling joint installation guide. Follow it close. How to install steel dismantling joint. Step by step. Common mistakes when installing dismantling joints around pumps? Overlooking balance.

Designing for Easy Valve and Pump Replacement from Day One

Dismantling joints equal reserved space for installs or removes, plus axial limits. In valve rooms and pump houses, steel dismantling joints are must-consider design elements.

Plan them in from the start. Cuts maintenance costs over 20 years big time. Benefits of steel dismantling joints. Clear and lasting.

Designing pipelines for easy maintenance. Smart move. Why designers should specify dismantling joints around valves and pumps? For long-haul savings.

Sometimes projects skip these, then regret it later. Better to think ahead.

FAQ

Q: What is a dismantling joint used for?

A dismantling joint is used to provide adjustable length in flanged pipelines, making it easier to install, remove, or replace valves, pumps, flow meters, and other components.

Q: How do dismantling joints simplify valve and pump replacement?

They create extra axial space by adjusting the sleeve length, allowing equipment to be removed without cutting pipes, reducing labor and shutdown time.

Q: Are dismantling joints suitable for high-pressure pipelines?

Yes. Steel dismantling joints with restrained tie rods are designed to handle axial thrust forces and are commonly used in high-pressure water, industrial, and pump station pipelines.

Q: Where should dismantling joints be installed in a pipeline system?

They are typically placed on both sides of valves, around pumps, and near equipment that requires periodic maintenance, especially in confined valve chambers and pump rooms.

Q: What factors should I consider when selecting a dismantling joint?

Key factors include pipeline diameter, pressure rating, flange standard, axial adjustment range, material, corrosion protection, and compatibility with the installed valve or pump.