Flexible flange adaptors provide a handy fix for one of the usual problems in pipeline setups: pipes that don’t line up right. This can happen from heat changes, setup mistakes, or small shifts in the ground. Exact matches between flanged pipe parts are hard to get. So, do these adaptors truly fix it? In lots of actual situations, they do—if you pick and put them in correctly. They handle small differences without hurting the system’s strength or how it works.

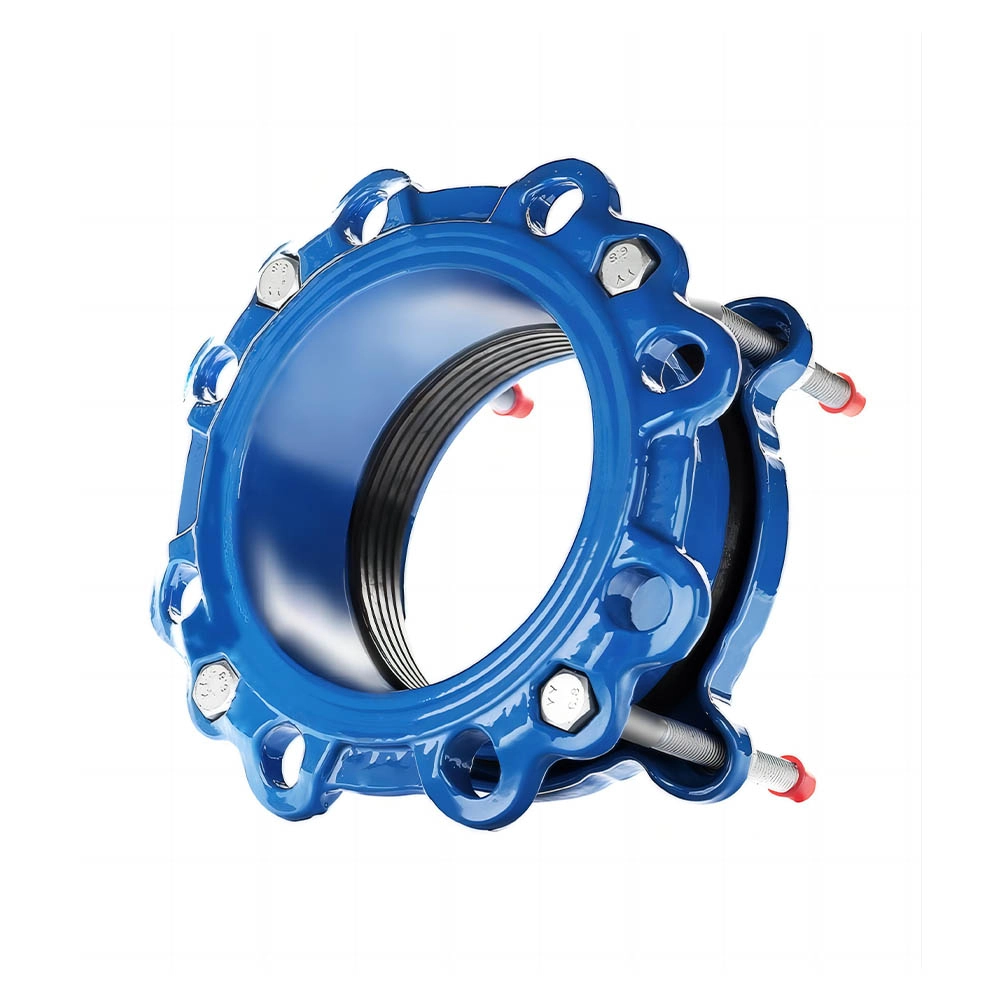

Flexible Flange Adaptor

Purpose and Functionality in Pipeline Systems

A flexible flange adaptor is made to join two flanged pipe ends that might not match up well. It gives enough room to deal with:

- Angular shifts (often up to 3°–5°)

- Small lengthwise moves

- Minor side offsets

This bendiness stops stress from building up. That could lead to leaks or harm over time. The adaptor seals tight around the joint. It keeps the inside pressure safe while allowing little moves or shakes in the pipeline. This matters a lot in buried or underground spots. There, soil changes or temperature swings can move pipes as time goes on.

Construction and Materials Used

The usual build for a flexible flange adaptor includes:

- A ductile iron body for good toughness and lasting power

- Gaskets from EPDM or NBR rubber for sealing against chemicals and pressure

- Stainless steel bolts and fasteners to fight rust

What materials you pick affects how it performs. For instance, EPDM gaskets hold up well against water and light chemicals. NBR works better for oils and fuels. Choosing the right mix makes sure the adaptor takes on not just heavy loads, but also weather and fluid challenges.

Types of Pipe Misalignment Addressed by Flexible Flange Adaptors

Angular Misalignment in Pipeline Installations

Even tiny angle differences between flanges can cause uneven gasket squeeze and leak dangers. A flexible Adapta ya Flange helps keep even contact on the gasket despite these small turns. It preserves the seal and overall balance.

Axial Displacement Between Pipe Segments

Pipelines often face lengthwise shifts from heat growth or shrinking. A well-chosen flange adaptor makes up for this movement—usually just a few millimeters—without too much strain on the joint. It works like a buffer between stiff parts.

Lateral Offset and Its Compatibility with Adaptors

These adaptors aren’t a full fix for big shifts. But they can handle small side moves—often less than 10 mm based on the type. For bigger ones, you might need other tools like expansion joints or to move the pipe again.

Key On-Site Advantages of Using Flexible Flange Adaptors

Reduction in Installation Time and Labor Costs

Lining up during pipeline building takes a lot of time. These adaptors make it easier by allowing small mismatches. They cut down on expensive fixes or special tools. Teams can finish the job quicker and with fewer changes.

Enhanced System Reliability and Leak Prevention

Flexible adaptors keep a steady seal even with pressure changes or ground settling. This lowers the chance of joint breaks from ongoing stress or shaking over time.

Versatility Across Pipe Materials and Sizes

Another plus of flexible flange adaptors is how they work with different pipe kinds—ductile iron, steel, PVC, even GRP. Manufacturers like Conflex, who focus on industrial pipeline links, provide adaptors in various sizes and setups. These are suited for water, oil, and gas lines.

Common Limitations and Potential Failure Modes

Mechanical Stress Beyond Design Specifications

These adaptors aren’t magic. If a pipeline goes over the suggested mismatch limits, it can cause gasket push-out or cracks in the flange body. Running past rated pressure or heat can lead to the same issues.

Corrosion and Material Degradation Over Time

Exposure to weather—wetness, chemicals, soil acid—can wear down gaskets or rust unprotected metal bits. If you don’t pick materials right for the spot, damage happens fast.

Improper Installation Practices Leading to Leakage

Uneven bolt tightening, dirty flange surfaces, or wrong gasket spots are frequent reasons for early leaks. These mistakes you can avoid hurt sealing and cut short the part’s life.

Criteria for Selecting the Right Flange Adaptor for Misalignment Issues

Assessing the Type and Degree of Misalignment Present

Before picking an adaptor, measure all the shifts: angular, axial, lateral. Then match them to what the adaptor can do, as the maker says. Don’t guess; check it out.

Matching Pressure Ratings and Pipe Specifications

Make sure the adaptor‘s pressure level fits your system’s working range. Also check if the flange hole pattern matches (like PN16, ANSI 150). Pipe material should fit too—steel pipes need different grip than PVC ones.

Considering Environmental Conditions and Media Type

The stuff flowing through the pipeline counts as well. If it’s water, EPDM might be enough. For oil fluids, NBR is better. And if your pipeline is buried or outside, choose rust-proof metals. Add protective coats if needed.

Installation Techniques That Ensure Long-Term Performance

Pre-installation Inspection and Surface Preparation

Always clean the joining surfaces well. Even tiny dirt can stop proper gasket squeeze. Check all parts—gaskets in particular—for damage before putting together.

Proper Bolt Tightening Sequence and Torque Application

Use a cross pattern when tightening bolts. This ensures even pressure around the flange. Apply torque in steps—start at 30%, then 60%, then full—as per product instructions from reliable manufacturers like Conflex.

Situations Where Flexible Flange Adaptors May Not Be Suitable

Severe Misalignments Beyond Tolerance Limits

If shifts go over the adaptor’s design limits, it’s not smart to push it. You might need mechanical expansion joints or custom fittings made for bigger moves.

High-Vibration or Dynamic Load Environments

In places like pump outlets or machine links where shaking is common and strong, ongoing motion can tire out the adaptor’s parts over time. Use locked joints or couplings with shake-damping instead.

Systems Requiring Rigid Structural Integrity

Some pipeline setups need total stiffness—like supports in factories or sea platforms. Here, flexible adaptors don’t help; welded joints or grooved fittings work better.

Frequently Asked Questions About Flexible Flange Adaptors

How much misalignment can a flexible flange adaptor handle?

Tolerance varies by product but typically ranges from 3°–5° angular deviation. Axial movement is generally limited to a few millimeters. Always refer to manufacturer specifications.

Can these adaptors be reused after disassembly?

Reusability depends on gasket condition, operating history, and exposure. Gaskets may need replacement even if metal parts are intact.

Are flexible flange adaptors compatible with buried pipelines?

Yes, if made from corrosion-resistant materials. Proper wrapping/coating is recommended for long-term protection underground.

What maintenance is required after installation?

Periodic inspection for leakage, bolt loosening, or corrosion is advised. Retorqueing bolts may be necessary after initial operation cycle.

Do I need lubrication during installation?

Yes—light lubrication on bolt threads and gasket seating surfaces (if permitted) can help achieve uniform compression and ease assembly. Always follow manufacturer guidance here.

By handling alignment problems well while keeping seals strong, flexible flange adaptors play a key role in today’s pipeline setups—especially when you pair them with smart choices and careful setup ways.